MC Machinery's Sinker EDMs Feature AI Adaptive Control

The artificial intelligence adaptive control technology is said to help optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

Share

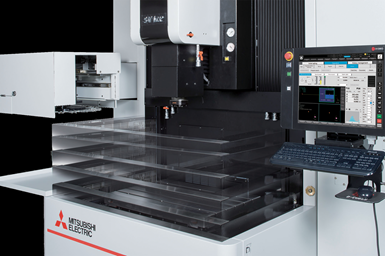

Photo Credit: MC Machinery

MC Machinery’s latest EDM and precision milling technology includes wire and sinker EDMs, machining centers and automation. The company, a subsidiary of the Mitsubishi Corporation, is a supplier and servicer of fabrication and milling equipment, including Mitsubishi lasers, EDMs and automation systems.

The new Sinker EDMs feature artificial intelligence (AI) adaptive control technology. The company says the Mitsubishi SV12P and SG12 sinker EDMs optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

The AI technology is said to make logical use of condition-monitoring data. For example, these new machines can diagnose real-time problems within the burn and directly modify specific parameters for a stable and accurate output. This enables machine operators of all experience levels to produce quality results in complex cavities and shapes.

Because the AI technology analyzes current sensor data to determine optimal conditions, it reduces overall electrode wear and costs. According to the company, by monitoring these parameters, the machine operates more efficiently and can more accurately predict machining times.

Related Content

-

Wall Colmonoy Acquires New Wire EDM From Sodick

The company will use the new wire EDM machine to increase capacity, improve cycle times, achieve tighter tolerances and improve surface finishes.

-

MC Machinery EDM Offerings Provide Optimized Performance

MC Machinery’s Mitsubishi SG12 and MV2400 EDMs provide ergonomic and efficient operations.

-

Sodick Die-Sinker EDM Fits Range of Automation Needs

The Sodick ALG EDM series doubles motor response speed for the development of accurate, high-quality molds, and is equipped with automated features for continuous operations.