MC Machinery Systems, Inc.

Mitsubishi EDM

85 Northwest Point Blvd.

Elk Grove, IL 60007 US

630-616-5920

info@mcmachinery.com

CONNECT

IS THIS YOUR COMPANY?

Video Gallery

Mitsubishi Laser Automation - Blank-to-Bend with ASTES4-Advanced | MC Machinery

MC Machinery, a US subsidiary of Mitsubishi Corporation, presents their Blank-to-Bend unmanned laser automation solution ...

Mitsubishi Press Brake Automation - RIBS (Robotically Integrated Bending Solutions) | MC Machinery

Press brake automation just got smarter! Introducing RIBS (Robotically Integrated Bending Solutions)—a cutting-edge integration ...

Mitsubishi Laser - FV 5-Axis Fiber Laser | MC Machinery

For more information on the new Mitsubishi FV 5-axis fiber laser, visit: https://www.mcmachinery.com/product/fv-5-axis-series/ ...

Mitsubishi Laser and Press Brake - FABTECH 2023 | MC Machinery

To learn more about MC Machinery Systems, visit us online at: www.mcmachinery.com.

As Seen On 91ÊÓƵÍøÕ¾ÎÛ

MC Machinery Systems, Inc. Supplies the Following Products

- All Other Workpiece Handling, Loading & Feeding Equipment not specified

- CNC Drilling & Tapping

- CNC Turn/Mill Machines

- Cut-off Lathes

- EDM Filtration Equipment & Supplies

- EDM Tooling

- Electrode Materials, EDM Wire & Supplies

- Encoders/Resolvers

- Graphite Milling

- Horizontal CNC Turning

- Laser Accessories & Supplies

- Laser Cutting Systems

- Laser Marking Systems

- Lasers, CO2

- Leasing & Financing

- Machining Flex Lines

- Nano & Micro Machining

- Pallet Changers/Shuttles & Programmable Transfer Devices

- Planer, Gantry & Bridge Type Milling

- Press Brakes - Mechanical & Hydraulic

- Ram Type (Die-Sinking) CNC EDM

- Replacement & Repair Parts

- Robots, Industrial

- Universal

- Universal Milling Machines

- Vertical CNC Turning Centers

- Vertical, Five-Axis

- Vertical, Up to Four-Axis

- Welding Machines, Electron-Beam

- Wire Type EDM

Trade Names Offered by MC Machinery Systems, Inc.

- MC Machinery Systems, Inc. Mitsubishi EDM/Laser

Editorial, News, and Products

-

MC Machinery Systems Inc. Appoints Marketing Manager

Michelle Moody will lead marketing strategy, brand development and digital initiatives to enhance the company’s presence in the manufacturing industry.

-

Video: Machining and Directed Energy Deposition (DED) Additive Manufacturing Aid One Another and Work Together

DED parts made by a machine tool provider illustrate various ways the strategic consideration of either metal 3D printing or machining helps the other process.

-

MC Machinery Displays EDM, Precision Milling, 3D Printing

IMTS 2024: MC Machinery Systems showcases an array of EDM and precision milling tools, as well as a wire laser metal 3D printer.

-

MC Machinery Announces General Manager Promotions

MC Machinery Systems promotes Brian Howard to general manager of purchasing/logistics and George Johnson to general manager of the Consumable Products Group.

-

MC Machinery Systems Promotes VP of Sales for Fabrication, Senior Laser Applications Manager

The company has promoted Shane Herendeen to fabrication division vice president of sales, as well as Michael Koch to the position of senior laser applications manager.

-

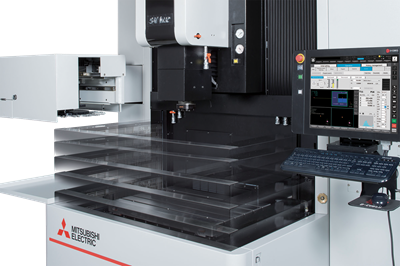

MC Machinery EDM Offerings Provide Optimized Performance

MC Machinery’s Mitsubishi SG12 and MV2400 EDMs provide ergonomic and efficient operations.

-

MC Machinery's Sinker EDMs Feature AI Adaptive Control

The artificial intelligence adaptive control technology is said to help optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

-

MC Machinery to Host Grand Opening for Southeast Technology Center Oct. 6

Catered food and machine demonstrations — including lasers, EDMs, press brakes and automation systems — will celebrate the opening of the 16,000-square-foot facility.

-

EDMs Spark Interest

MC Machinery is showing off its suite of EDMs and milling machines designed for die/mold applications.

-

MC Machinery Welcomes New Hires

Alexander Wright and Erik Sweede join MC Machinery.

-

MC Machinery Adds J.M. Grisley as EDM, Milling Dealer

The company has named J.M. Grisley Machine Tools as a new dealer for its EDMs and machining centers.

-

MC Machinery Adds Prosper Machine Tools as Distribution Partner

EDM supplier MC Machinery Systems added Prosper as distribution partner in Texas for its line of Mitsubishi wire and sinker EDMs and high-precision machining centers from OPS Ingersoll and Roku-Roku.

-

MC Machinery to Showcase EDMs and More

Eastec 2021: MC Machinery will highlight two EDM machines, a five-axis VMC and more in booth 1426.

-

Machining 101: What is Electrical Discharge Machining?

Electrical discharge machining, or EDM, is a non-contact form of machining that projects sparks from an electrode or wire to vaporize material of any hardness.

-

MC Machinery GX-F Advanced Fiber Laser System Simplifies Use

MC Machinery’s GX-F Advanced Series of fiber laser systems uses artificial intelligence to enhance operational simplicity and self-correct bad cuts.

-

MC Machinery Opens Southeast Technology Center

MC Machinery has opened a new technology center in Concord, N.C. to act as a showroom and demo station for its range of manufacturing solutions.

-

MC Machinery Launches Manufacturing Podcast

MC Machinery has launched its Minds on Manufacturing Podcast, which it intends to be an interesting, informative show for manufacturers across the industry.

-

Use Your Machinists to Make Dies

By systemizing die making into repeatable steps, Dies Plus, a division of Otto Engineering, is using its machinists to effectively make dies. This solution relies on a paperless color-coding system to convey the tolerances machinists need to hit in order for tool and die makers to do the final fitting.

-

Cool Tricks: How to Photograph Sinker EDM

Sometimes it takes a little extra effort and ingenuity to solve a problem. In the case of the February 2020 cover of 91ÊÓƵÍøÕ¾ÎÛ, it took a lot of each — and a cheap plastic spaghetti container.

-

Inside the Sinker EDM Process, One Spark at a Time

Successful sinker EDM operations rely on understanding the relationship between each individual spark, the electrode and the workpiece.

-

June 2019 Product Spotlight: Electrical Discharge Machining (EDM)

This month’s Modern Equipment Review Spotlight focuses on different types of electrical discharge machining equipment.

-

EDM from MC Machinery Handles Larger Parts

MC Machinery’s MV2400-ST, an electrical discharge machine, is specifically designed for larger-part production, capable of performing submerged cutting up to 16.5" deep.

-

EDM Features Touchscreen Control

Eastec 2019: MC Machinery Systems’ MV1200-R advance features the M800 control, the latest addition to the MV Series.

-

Fiber Optics Improve EDM Spark Monitoring, Wire Life

This controller uses fiber-optic cables to overcome major hurdles in monitoring EDM spark output, improving wire life and reducing voltage consumption.

-

EDM Provides Friction-Free, Accurate Column Movement

IMTS 2018: MC Machinery’s MV2400-ST EDM is designed for larger-part production and is capable of performing submerged cutting as low as 16.5" deep.

-

Laser Control Features Tablet-Style Touchscreen Interface

Mitsubishi Laser has added its M800 control technology to the Advanced 800-series eX-F fiber laser machine.

-

System Provides Accurate 2D, 3D Inspection of Sheet Metal Parts

MC Machinery Systems Inc. has partnered with InspecVision Planar US to offer the latter’s high-speed integrated 2D and 3D measurement system.

-

Fiber Laser’s Eco Mode Reduces Costs During Standby

MC Machinery’s fiber laser offering has expanded to include the SR-F series from Mitsubishi.

-

EDM Control Displays Various Information in Single View

The M800 EDM control from MC Machinery Systems is included with Mitsubishi wire EDMs to increase productivity and help keep track of production jobs.

-

MC Machinery Systems Opens New Headquarters

The company hosted a festival and seminars to celebrate the Elk Grove, Illinois, grand opening.

-

MC Machinery Systems Officially Opens New Headquarters

Last week, MC Machinery Systems Inc. officially opened its new, larger headquarters in Elk Grove Village. Cynthia Kushtush from sister publication Moldmaking Technology was there to cover it. Here is a small sampling of what she saw.

-

Hot Temperatures (and Technologies) at Eastec 2017

Eastec’s peculiar Massachusetts venue offered the chance to sample a broad variety of advanced manufacturing technologies. Here is a slideshow and some impressions from the trade show.

-

MC Machinery Systems Breaks Ground for Headquarters

The new corporate headquarters are slated to be completed December 2016.

-

June 2016 Product Spotlight Slideshow: EDM

This month’s Modern Equipment Review Spotlight focuses on electric discharge machines, or EDMs.

-

May 2016 Product Spotlight Slideshow: Laser & Waterjet

This month’s Modern Equipment Review Spotlight focuses on machines for laser and waterjet cutting.

-

Zinc-Coated EDM Wire Speeds Cutting, Improves Finish

MC Machinery Systems, a subsidiary of Mitsubishi Corp., offers its ZT Hybrid Wire for EDM machining.

-

Turning Center Enables Smooth, Heavy-Duty Cutting

MC Machinery’s LT-350 turning center is capable of machining hard materials for a range of applications.

-

Wire EDM Offers Non-Contact Shaft Design

Mitsubishi EDM’s MV1200R wire EDM features improvements over the company’s previous EDM models.

-

Bow Machining II

What does a bow say about manufacturing? Quite a bit, actually. Bows from Elite feature trigger parts machined through EDM, composite laminate upper and lower limbs cut with waterjet, and a riser and other components milled out of aluminum on a vertical machining center.

-

Machining Center for Fixtures

Mitsubishi EDM/Laser’s MCV 1000 machining center is a general-purpose machine for applications such as fixtures, mold base and secondary operations.

-

Don’t Discount the Small Stuff

At least in the short term, the most significant machine design changes aren’t always the most significant difference-makers on the shop floor.

-

Scratching the Surface

Although this shop has yet to fully explore the capabilities of a new wire EDM’s unique motion system and other precision-boosting features, more incremental improvements have already spurred management to order a second, identical model.

-

Behind the Curtain

Turnout for Mitsubishi EDM’s open house last week indicated a high level of interest in the company’s new line of Wire EDMs. However, despite being introduced with less fanfare, a few other new product lines shed light on the company’s future direction.

-

Entry-Level Waterjet Designed to be Reliable, Affordable

Mitsubishi's MWX3 waterjet is designed for production-environment applications.

-

Cylindrical Drive Shaft Motors Replace Ballscrews on Upgraded Wire EDMs

In addition to linear shaft motor technology, the MV series from Mitsubishi EDM now features a redesigned automatic wire rethreading system, an enhanced power supply and high speed communication in the servo system, among other advances.

-

Pump, Motion System Expand Waterjet Possibilities

Two Mitsubishi waterjets from MC Machinery Systems equipped with 125-hp, 90,000-psi pumps from KMT Waterjet Systems enable this manufacturer to cut thicker material faster and more accurately.

-

EDM Solution Accommodates Tall Workpieces

The FA30V Advance wire EDM from MC Machinery Systems accommodates tall workpieces for large-part manufacturers.

-

EDM and Complementary Technologies

The company’s offering of EDM, hole popper and waterjet technologies includes the FA10S Advance wire EDM, the EA12V sinker EDM, the ED2000M small-hole EDM drill and the DX44 waterjet. The FA10S Advance wire EDM features the company’s M700 series control.

-

Laser Produces Quality Cutting Surface Finish

Mitsubishi Laser’s next generation LVPLUSII laser cutting machine adds performance and productivity-enhancing features to the original design.

-

Automated Cell Combines Wire EDM, Waterjet Technologies

Mitsubishi’s MD+CELL combines the MD+PROII wire EDM with a Suprema DX44 waterjet for high speed and precision in one automated unit, minimizing operator intervention and maximizing unattended run time. The MD+CELL employs a Mitsubishi MELFA six-axis robot to transfer rough-cut pieces from the waterjet to EDM machine for finishing.

-

Vision System Brings On-Machine Measurement To Ram EDM

Vision technology tailored to ram EDM allows shops to measure a part as it remains fixtured on a spark-erosion machine.

-

Large Wire EDM Unit Gives Shop Room to Grow

This wire EDM job shop in Wisconsin acquired a submerged cutting wire machine that lets it handle larger, taller workpieces than just about any other job shop in the country. The new machine has a “column-up” option that adds a riser block between the X-axis saddle and the Z-axis column casting to give it exceptionally tall cutting capacity. The machine was installed in November 2007.

-

Big EDM Seals The Deal

Submerged cutting of large workpieces such as honeycomb seals for jet engines calls for a larger capacity wire cut machine.

-

A Highly Complementary Combo

Wire EDM and abrasive waterjet go together well, especially for cutting aluminum.

-

Under One Roof

In bringing multiple manufacturing processes in-house, this medical shop parallels its customers' efforts to be one-stop sources for hospital equipment.

-

Laser Facilitates Quicker, Thicker Cutting

Tornqvist, Inc., established in 1876, manufactures component parts for the industrial, architectural and pharmaceutical industries. Three years ago, the Wayne, New Jersey company moved into a new 27,500-square-foot facility to accommodate its steady increase in business. This relocation was a crucial step in preparing for a successful future, says Ken Grimbilas, vice president of the business since his family assumed ownership in 1986.

-

Meeting Production Requirements For Medical

You might think that medical manufacturing always calls for complicated machine tools with lots of high-tech features for applications where no expense can be spared. This is not true. Medical manufacturing is often about economical production, where affordability, reliability and compactness are key values.

-

Running EDM Economically

Many shops are taking a closer look at the cost of operating a machine tool. How much energy does it consume? Does it create excessive heat, making the shop air conditioning work harder? Does it stretch the life of cutting tools and consumables?

-

EDM Part Precision Imperative To Racecar Manufacturer

To meet a challenge that requires precision machining capability, Joe Gibbs Racing ordered two EDM machines and has been successful in machining the smallest of parts ever since.

-

Classy Shop, Classy Cells

The automated EDM cells in this shop are distinguished by their thoughtful design and careful attention to detail--as is the rest of the shop.

-

The Indispensable Toolroom

By steadily improving its equipment and processes, a toolroom becomes the fountainhead of a worldwide manufacturing operation.

-

Where Wire EDM Is A Workhorse

This shop finds the process practical, productive and predictable, an indispensable technology that supports all of its manufacturing capability.

-

Silicon Powder Additives Proven Safe And Effective In EDM

As with any new EDM innovation, the effectiveness of various powder finish processes will be debated. Likewise, dual-tank systems will be compared to single-tank systems. Here's a viable answer to that debate.

-

Fine Wire Is Just Fine

As parts get smaller and smaller, using EDM wire as small as 0.001 inch in diameter to cut these workpieces becomes an attractive option—actually, the only option.

-

Anti-Electrolysis Developments In Wire EDM

Originally, wire EDM had two things going against it. It was slow, and often it left an undesirable surface finish. In the last few years, wire EDM builders have fixed the speed problem. Now they're well on their way to fixing the surface finish problem.