Wintriss to Showcase New OEE and Data Collection Software Features

Eastec 2021: Wintriss claims the software can increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks.

Share

will demonstrate new features in its overall equipment effectiveness (OEE) and data collection software at Eastec 2021, booth 5012.

Wintriss claims the latest functionality in ShopFloorConnect software promotes increased efficiency and reduced downtime, including when remote monitoring is required. The software can increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks.

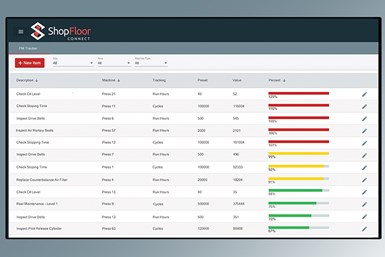

ShopFloorConnect collects downtime and production efficiency data from every machine in a variety of industries, including discrete manufacturing, metal forming, metal fabrication packaging, food and beverage. The data is displayed in real time, and manufacturing reports are produced in a variety of formats. At Eastec, Wintriss will introduce the new ShopFloorConnect preventative maintenance (PM) tracker, which enables users to track items by run hours or machine cycles, issue targeted alerts when an item requires PM and track the maintenance work history for all machines.

ShopFloorConnect 6.0 includes a new interface that Wintriss claims will enable users to set up two-way data sharing with any ERP or MES software.

Related Content

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.