CNC & Machine Controls

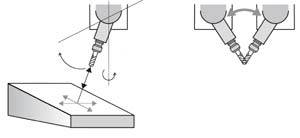

Curve Interpolation For Less

When the CNC executes the program faster, a higher feed rate becomes possible. Precisely this benefit has compelled many mold makers in particular to inquire about NURBS.

Read MoreFinding The Current States Of Your Control

You probably know that most current CNC controls will display all currently instated modes (commonly set by G codes). With one popular control, this is part of the program check display screen function.

Read MoreThe DRO You Wear

Dubbed iPRO for interactive personal readout, this DRO system is wearable, wireless and voice activated. Each of these features is remarkable in its own right. Combined, however, they make the most futuristic DRO system you are likely to encounter.

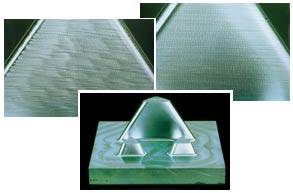

Read MoreCNC Technology For Mold Applications

Accessible control features play an expanding role in mold machining.

Read MoreTool Management System Complements DNC

It quickly became apparent to this company that handling the many tools - knowing where the tools were and how many were available - was the horse, and the DNC system was the cart.

Read MoreMold Machining In Motion

This shop's strategy for limiting lead time on large molds affects the choice of machine tool. It also affects who does the programming.

Read MoreController Helps Meet Demand For Foreign Oil

The cutting of thousands of slots in extensive lengths of pipe requires large-scale machining, and the demand for such pipe is steadily increasing as Middle East oil sources become less dependable. Controls on these machines are crucial.

Read MoreHow Should Your Operators Handle Sizing Changes?

All current model CNC controls allow offsets to be changed during the execution of the CNC program. That is, operators can change an offset during a production run while the machine is running.

Read MoreOverriding The Skills Shortage

With experienced operators in short supply, this shop developed a software solution to compensate.

Read MoreLinear Motors Shorten Production Time

Linear motors account for part of the reason why DaimlerChrysler's Stuttgart, Germany, manufacturing facility has been able to nearly double the productivity of machining centers producing automotive cylinder heads.

Read More