Cutting Tools

Drilling “Invisible” Holes

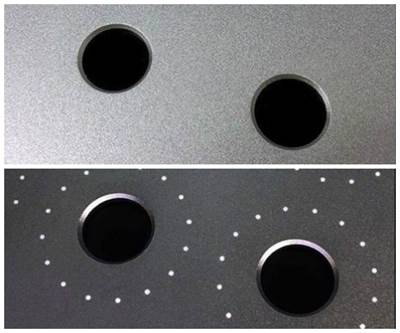

UV laser micromachining makes it possible to drill holes that are not visible to the human eye—until they are meant to be seen, that is.

Read MoreReplaceable Drill Head Supports Deep Hole Making at Lower Cost

Sumitomo Electric Carbide expands its SMD replaceable drill head line to include 12×D drills.

Read More5ME Authorizes Star SU, Fullerton Tool to Make, Distribute Cryogenic Tooling

Fullerton and Star SU can now make, market and sell 5ME’s BlueZone brand in North America.

Read MoreThrough-Coolant System for Use with Emulsion, Pure-Oil Coolants

Rego-Fix offers an addition to its line of retrofit ReCool coolant-through systems, the ReCool RCR/ERM.

Read MorePrecision Hole-Making Experts Come Together

Allied Machine & Engineering Corp, a manufacturer of hole-making and finishing tooling systems, has purchased a majority of the shares of Wohlhaupter GmbH of Frickenhausen, Germany, Wohlhaupter USA and Wohlhaupter India. The company is best known for its innovative boring tools.

Read MoreMilling Tool Line Features Single-, Double-Sided Inserts

Komet’s new line of milling tools is comprised of over 280 items, including 63 new imperial (inch) and 63 new metric bodies.

Read MoreModular Interface Designed for Carbide Cutting Tool Heads

Haimer’s Duo-Lock modular interface system is designed for carbide cutting tool heads.

Read MoreLarge-Diameter Drills Mount without Removing Tool from Spindle

Tungaloy has expanded its DrillForce-Meister series of interchangeable-tip drills.

Read More3 Next-Generation Gear Finishing Processes

Vibratory finishing, centrifugal barrel finishing and turbo-abrasive machining are the three top techniques for finishing gears, improving performance and extending service life.

Read MoreOptimized Machining out of the Box

Four tooling-related companies partner to supply dynamically stable milling for improved productivity on existing machine tools. Users do not have to measure the dynamics of their machines. Instead, tooling tailored to the machine arrives as a complete assembly, along with software for quickly determining the parameters that tooling can be used to achieve.

Read More