Machines

Advanced Technology Drives 40 Years of Manufacturing

Mazak has been manufacturing machine tools in Florence, Kentucky for 40 years. The growth and development of the production technology deployed in this plant reflect the most important advances in manufacturing during this span—from enhanced flexible manufacturing systems and multi-tasking part processing to automation and digital-driven manufacturing.

Read MoreMultitasking Five-Axis Machining Center for Large Gears

Mazak's Integrex e-1550V/10 multitasking five-axis machining center suits the production of large gears.

Read MoreClamping Options for Five-Axis Machining

In five-axis machining, the workholding has to get out of the way. The wrong choice of clamping risks collision and can obscure one of the principal benefits of a five-axis machine.

Read MoreAdvantages of a B-Axis Swiss-Type

Learn how a Northeastern shop leverages a Swiss-type lathe with a B-axis milling spindle to produce small batches of complex parts.

Read MoreRobot Eliminates WIP, Improves Efficiency

Automating loading/unloading of two new Mori Seiki lathes and a part wash/dry system with a FANUC robot from Automated Cells and Equipment enabled the company to eliminate an initial testing process as well as reduce labor and WIP.

WatchBonded Abrasives Promote Grain Adhesion for Versatility

Norton Abrasives, a brand of Saint-Gobain, offers its Vitrium3 bonded abrasive products, featuring a bond chemistry that promotes grain adhesion for improved versatility across a range of applications.

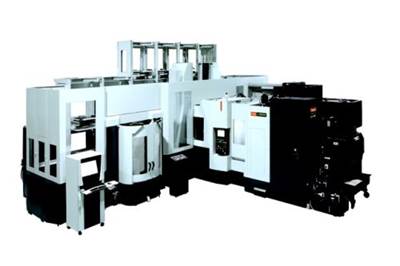

Read MoreManufacturing Cell Enables Large-Part Production

A "done-in-one" manufacturing cell for large part production consisting of an Orbitec 20 machine, an Integrex multitasking machine and a Palletech automation system is now available from Mazak.

Read MoreHMC Enables High-Speed Change-Overs

Tongtai's HA-400II horizontal machining center, available from Absolute Machine Tools, features a rigid, FEA-tested design with a cast iron machine frame and three-point leveling system.

Read MoreThe Costs and Benefits of Horizontal Machining

The shift from vertical to horizontal machining was even more expensive than this shop anticipated. It was also more valuable. Most of the shop’s machining centers are HMCs now—here’s why.

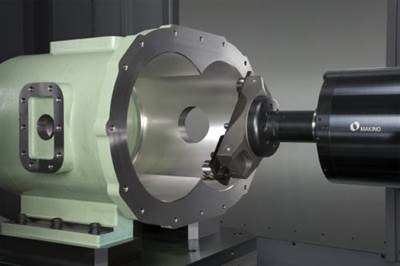

Read MoreHMC Expands Work Zone

Makino's a81nx horizontal machining center increases the size of the work zone from other NX series machines to accommodate large parts requiring diverse tool types and sizes.

Read More