Software

Smarter Machining Squeezes More Productivity And Profits From The Shop Floor

To increase efficiency and productivity, this Canadian mold shop began programming NC cutter paths on the shop floor, in real time.

Read MoreSetting The Stage For Production

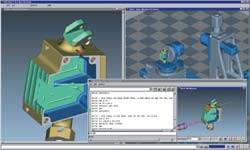

This software is an external verification/optimization tool that provides faithful representations of first-run machining processes. This affords the opportunity to rectify machining conflicts before the first chip flies.

Read MoreCAD Product Takes A New Direction

This CAD software is the first commercial application based on the GeMS++ object-oriented database and memory management tools developed by Honeywell in partnership with the U.S. Department of Energy.

Read MoreWhat CAM Functions Do Moldmakers Want?

In development of CAM software products, vendors must establish priorities and allocate resources accordingly. The priorities are primarily determined by the market or markets they wish to serve and the product's user.

Read MoreCAM at a Crossroads

In the world of metalworking, the CAM part of CAD/CAM (computer-aided design/computer-aided manufacturing) generally means software for programming CNC machine tools. Currently, most of the advances and innovations in CAM software are coming from the smaller software companies devoted to this application.

Read MoreIs Manual Programming Really Important?

I am often questioned about the scope of this column. The most common question is: "Why do you continue to discuss manual programming techniques when almost all companies are using CAM systems?" Aside from the fact that other columnists are addressing issues related to computer integrated manufacturing, I believe that a firm understanding of manual programming is of paramount importance to all CNC people.

Read MoreScalable Measurement And Quality

Machine shop owners face a fundamental conflict in their efforts to make metrology an integral part of manufacturing processes. On one hand, the critical relationship between quality and profitability makes metalworking professionals reluctant to change tried-and-true methods. On the other hand, however, the drive for better productivity demands that every aspect of the manufacturing process be rationalized and increasingly divorced from the realm of human subjectivity.

Read MoreNetworked Machine Shop Learns The Value Of Proper Grounding

In business for more than 22 years, McAfee Tool&Die Inc., uses conventional machine tools, stamping presses and injection molding machines, as well as more than a dozen computer numerical control (CNC) machine tools, including three 3-axis machining centers, six wire electrical discharge machines (EDM), three laser-cutting machines and a CNC turning center.

Read MoreThe Long View On Short-Run Work

This shop doesn’t know what parts it will machine tomorrow, but it has a good idea who its customers will be well into the future.

Read More