Software

Moving 3D Programming To The Shop

New CAM systems are not just making shopfloor programming of 3D mold cores and cavities practical, they're making it easy. Here's a look at the technology and how two Detroit tool shops are making off-line and shopfloor programming work together.

Read MoreMinnesota Manufacturer Integrates Software For A Mini-MES

Buying specific, flexible software products, each geared to one particular need, and integrating them, provided this shop with its own 'mini manufacturing execution system.'

Read MoreOpen-Architecture CNC Closes Servo Loop In Software

The company developed Compact II, an NC programming language that quickly became one of the most widely used in the metalworking industry.

Read MorePushbutton NC Programming

With numerical control (NC), shops learned how to automate the machining process. Now, with today's CAM software, they are learning how to automate the NC programming process.

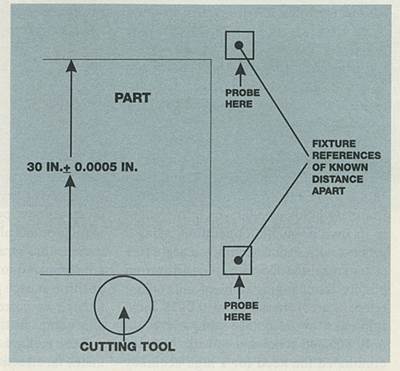

Read MoreBreak The Accuracy Barrier

"Reference comparison" uses probing to hold accuracies tighter than inherent process error.

Read MoreCAM And California Manufacturer Aim For 'Any Mold In Ten Days'

If self threading screws, accumulated out-of-tolerance buildup, warpage, impact resistance, cosmetic appearance, assembly to other parts and snap fits are not perfect, it's the scrap bin for expensive production.

Read MoreKey CNC Concept #6—Methods For CNC Programming

Presented here are three methods of developing CNC programs, manual programming, conversational (shop-floor) programming, and CAM system programming.

Read MoreKey CNC Concept #5—The Importance Of Program Formatting

Simplicity and consistency are the hallmarks of good programming.

Read MoreKey CNC Concept #10—Verifying CNC Programs Safely

For the most part, CNC controls will follow the instructions given in a program to the letter. With the exception of basic syntax (program formatting) mistakes, the CNC control will rarely be able to tell if a mistake has been made.

Read MoreKey CNC Concept #7—Know The Machine From An Operator's Viewpoint

This perspective for a good programmer is a practical one, since the CNC operator must understand the machine's basic components, its directions of motion, and all buttons and switches available on the machine tool itself.

Read More