Tooling

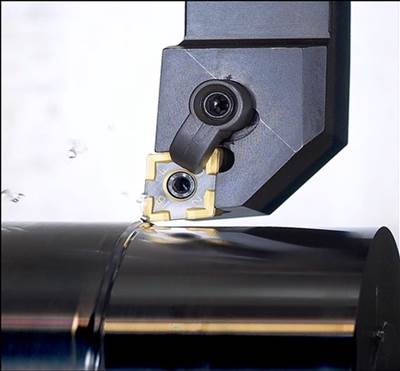

Steel Turning Grade Increases Tool Life

Seco Tools’ TP3500 grade offers improved edge toughness and wear resistance in demanding applications that require long and consistent tool life.

Read MoreAdjustment-Free Rotary Broaching Toolholder

Slater Tools’ 3700 series adjustment-free rotary broaching toolholder features an increased bearing capacity capable of producing larger forms than its previous two series, which were designed for Swiss-type machines.

Read MorePerformance Drills for a Variety of Materials

The HY-PRO CARB 3D and 5D drills from OSG feature point and flute geometry designed to reduce thrust forces and chip size, which enables higher feeds and metal removal rates.

Read MoreAlumina Fixtures For High-Temperature Brazing

Morgan Technical Ceramics’ Wesgo/Duramic business offers custom alumina fixtures designed to isolate and insulate metal components during high-temperature brazing processes.

Read MoreCatalog Features Tools For Increased Productivity

The 2010 full-color catalog from Imco Carbide Tool features case studies and user testimonials that include tips for increased productivity, sustained performance and extended tool life.

Read MoreVersatile Turning Geometry

ATI Stellram offers a versatile geometry for finish turning components ranging from steel to high-temperature alloys.

Read MoreTool for Shallow, High-Feed Cuts Speeds Roughing

“Feed fast, cut shallow.” This strategy, in combination with a cutting tool specifically designed to take advantage of it—the Power Feed+ from Ingersoll—enabled this shop to reduce cycle time on a tough prototyping job by a factor of five and increase insert life by a factor of six.

Read MoreWhen Spindle Speed is a Constraint

Though it won’t replace high speed machining, Boeing sees “low speed machining” as a viable supplement to higher-rpm machines. Using new tools and techniques, a shop’s lower-rpm machining centers can realize much more of their potential productivity in milling aluminum aircraft parts.

Read MoreVideo: Getting the Most Out of Your Standard Spindle

High spindle speed is not needed for high productivity, particularly with the right choice of cutting tool types. Techniques described in this tutorial video relate to plunge roughing, high feed milling and slotting.

WatchVideo: Plunge Roughing in Aluminum

Even in aluminum, plunge roughing can be an effective way to realize high productivity.

Watch