Articles

Increase Machining Efficiency through Machine Monitoring

A manufacturer that is distinctive for its attention to in-cycle machining productivity describes its efforts to obtain efficiency improvements outside of the machining cycle. The shop’s primary tool is a simple, daily, graphical recap that illustrates when each machine tool was and was not making parts.

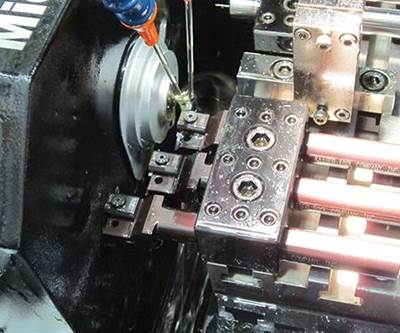

Read MoreMachining Micro Parts for Medical

This shop’s micromachining needs, primarily for medical components, ultimately led to the development of a new multifunction turning center platform geared toward producing tiny parts complete.

Read MoreA Virtual Approach to CNC Training

One way to take the fear of crashing an expensive machine out of CNC training is by using simulation software that features programming methods actually used on the shop floor.

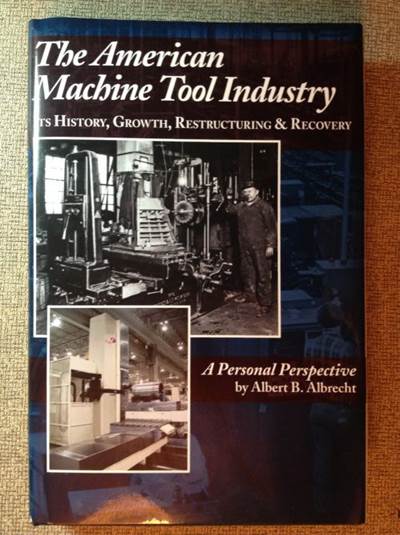

Read MoreA New Take on Machine Tool History

An enlarged, updated and revised edition of “The American Machine Tool Industry” by Albert B. Albrecht is now available. This new book includes a discussion and analysis of the industry's resurgence since the start of the new century, but retains the author’s personal but perceptive interpretation of its history when U.S. builders were the dominant force in the global machine tool industry.

Read MoreThe Value of Benchmarking

Our sixth-annual Top Shops benchmarking survey runs through Feb. 29. Learn why it’s valuable to participate.

Read MoreOnline Matchmaking Platform Focuses on Skilled Trades

Operating much like online dating sites, this new platform aims to connect job seekers and employers in industries ranging from manufacturing to construction.

Read MoreMusic above the Machining

An example of a little touch that makes a big difference: The music is uplifting and clear in this shop thanks to a sound system tailored to overcome the machines.

Read MoreWhat to Consider When Looking For Gage Calibration Services

Just as critical as the accuracy of the gage, finding the right lab to actually perform the calibration is a must.

Read MoreMoldmaker Speeds Production with 3D-Printed Fixtures

A 3D printer helps this mold manufacturer save time and money in making custom fixturing.

Read MoreFive-Axis Blends Require Minding Ballnose Tolerances

Proper symmetry, expressed via the end mill’s diameter and radius tolerance, is critical to ensure smooth surface finishes during five-axis contouring operations.

Read MoreVideo: Accelerated Blisk Milling

CAM and cutting tool companies develop a process for machining a titanium bladed disk in less than half the conventionally expected cycle time.

WatchSearching for Good News in the Manufacturing Skills Gap

While the current employment outlook is seemingly bleak, with a high number of manufacturers reporting a moderate to severe shortage of available, qualified production workers, there does appear to be a light at the end of the tunnel concerning the future of American manufacturing over the next decade.

Read More