Articles

Easing the Entry into Additive Manufacturing

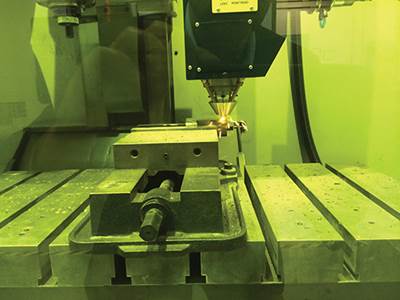

With funding from America Makes, Optomec and MachMotion worked together to develop a retrofit additive manufacturing system for machining centers.

Read MoreAdaptive Machining Makes a Robot More Productive

This system for machining and polishing turbine blades shows the value of software for inspection, toolpath calculations and adaptive machining working together.

Read MoreOne-Offs Without Tradeoffs

Does it have to be expensive to produce a one-off part? Does the one-off have to fall short of the manufactured part’s properties? A Boston-area 3D printer maker has an idea for how to produce components that are both low quantity and industrial quality.

Read MoreBroader Range of Applications Ahead for Ceramic Inserts?

Greenleaf's phase-toughened ceramic inserts could prove that this kind of technology has a future in more universal milling and turning applications.

Read MoreSurprises Uncovered at a Groundbreaking

Companies customarily mark new construction with a groundbreaking ceremony. Such an event to celebrate Hydrotech Inc.’s expansion of its suburban Cincinnati headquarters, however, revealed some unexpected facets to this diverse fluid power and automation solutions provider.

Read MoreVisiting Renishaw in the UK

The unveiling of Renishaw’s new 153,000-square-foot Innovation Center gave me a good opportunity to visit a company in the UK that I’ve known for years.

Read MoreDock in the House

Gear manufacturers can use this device in the measuring lab when it is docked, and also on the shop floor as a portable system when onboard inspection isn’t available.

Read MoreVideo: Collaborative Robots in Screw Machine Shop

Multi-arm robots working close to employees are noteworthy additions to this shop that got its start during World War II.

WatchBreaking Chips and Controlling Burrs when Machining Automotive Transmission Components

Chip control is the bane of every shop’s existence and knowing how to consistently break chips and control burrs in ductile steels like SAE 1018, 1020, and 8620 is the holy grail of the tooling industry. When a shop experiences chip control issues, it affects their bottom line either through machine downtime, scrapped or reworked components, lost inventory due to broken tools or even employee injury.

Read MoreTips on Breaking Chips When Turning Transmission Parts

Components for automotive transmissions are typically made of ductile steels such as SAE 1018, 1020 and 8620. Turning these parts is often plagued by problems with long, stringy chips. This article from Sandvik Coromant addresses the complex variables and strategic trade-offs that must be considered in designing the most effective insert for this application. The insights into the problem and its solution will help anyone think more clearly about vexing chip control issues.

Read MoreVise System for Quickly Clamping 16 Parts

A New York job shop minimizes setup and change-over time with a homegrown system consisting of closely spaced double-acting vises embedded into a plate. After using it for decades, the shop is now supplying this system to other shops.

Read MoreLarge-Part Grinding: Two Key Technologies

Developments in steady rest and in-process measurement technologies enable effective grinding of huge crankshafts.

Read More