Articles

Learn about 3D Printing of Large Parts at Amerimold 2015

At next week’s Amerimold show, Dr. Chad Duty will give complementary showfloor presentations on “Big Area Additive Manufacturing (BAAM).” Dr. Duty, a leading researcher at the Oak Ridge National Laboratory, will discuss how polymer-based additive manufacturing processes enable the production of large parts—parts as large as a full-sized car body. This technology promises to take time and money out of the tool and mold manufacturing process.

Read MoreMechanical Mockups for Maintenance Training

Maintenance is critical to the continued operation of military jets. This company has found a way to enable training without going to the expense of using a working engine.

Read MoreMultitasking Levels, MTConnect and Additive Mrf. Part of Tech Center Event

A recent open house at Mazak’s Chicago-area facility included not just various machines but also various ideas for thinking differently about machining.

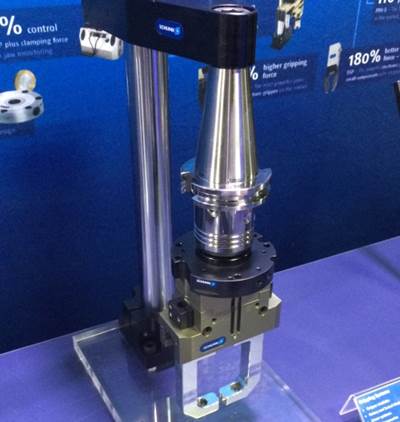

Read MoreVideo: Machine Tool Serves as its Own Robot

Schunk’s Gripper with Spindle Interface device enables a machine to load and unload workpieces on its own. See how.

Read MoreAutomated Laser Scanning Using a Collaborative Robot

This device is said to be the first programmable laser scanning system to enable automated 3D scanning, dimensional measurement and dimensional gaging leveraging a collaborative robot platform.

Read MoreVideo: Manufacturing of the Machined Direct Drive Drum Pedal

Music-industry manufacturer DW Drums discusses in-house production, machining of its new pedal design and working with extruded parts.

WatchMetrology Data That Drive Manufacturing

HxGN Live is the annual international conference sponsored by Hexagon, the global company best known in the manufacturing industry for its broad range of metrology equipment. With its recent acquisition of Vero software, Hexagon now has CAM software products to make metrology data a key driver of shopfloor productivity, as this year’s event made clear.

Read MoreSlideshow: Boosting Productivity with EDM

Features such as automatic threading, wear detection and ergonomic controls help to boost productivity in electrical discharge machining (EDM). View this month’s slideshow to learn more.

Read MoreC.R. Onsrud Partners with Pinnacle

With the expansion of its dealer network and growth in key markets including aerospace, this company’s custom-built equipment is catching the attention of a whole new audience.

Read MoreCollaborative Robots Cut Crown Leadtimes

A manufacturer of dental implants is realizing faster turnaround time for crowns by using collaborative robots to tend its machine tools.

Read MoreGarage Shop Evolves into CNC Tool Grinding Specialist

This tool grinding shop was able to transform itself into a specialty cutting tool producer with the adoption of a few advanced CNC tool grinding machines.

Read MoreProtection System Saves Spindles During Collisions

Collisions on a VMC can cause costly damage to the spindle as well as other machine parts, which prompted GF Machining Solutions to develop its Machine and Spindle Protection (MSP) feature.

Read More