Articles

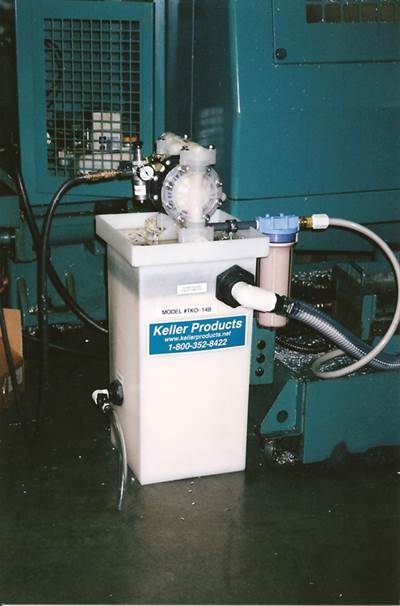

Coolant Filtration Yields Significant Savings

While many shop managers intuitively understand the importance of properly maintaining coolant, it's likely that few have calculated the actual cost savings of doing so. Keller Products says the 80-percent savings realized by one customer after installing pump/skimmer units is typical.

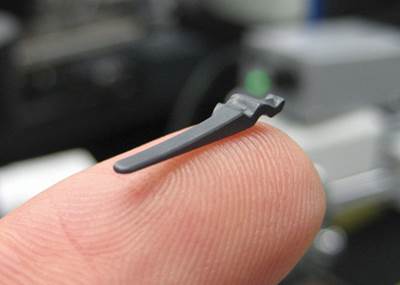

Read MoreIt Takes Firm Resolution To Master The Micro

This shop’s experience of successfully machining a micro aneurysm clip in silicon nitride ceramic points out the need to have CAD, CAM and CNC capability at high resolution—plus the commitment to pull it all together.

Read MoreValue First, Then Jobs

Investments that magnify our ability to create value will ultimately lead to more real jobs.

Read MoreThe Value Of Indexable-Insert Center Drills

This indexable-insert center drill, said to be an industry first, combines the drilling performance advantages of solid carbide with the positioning repeatability and quick-change benefits common to indexable-insert tooling.

Read MoreMachining Reimagined As A Lean Resource

It was a bold move for this company to install four new machine tools, including two turn-mills, at one time, but it was the only way to take the lean journey to a higher level.Â

Read MoreTen Ways To Maximize Profits In Any Economic Environment

In these tough economic times, it’s difficult to keep your company above water, let alone profitable. When business is booming, many shops focus on job completion and quality.

Read MoreCreating Cost Savings With Machine-Ready Blanks

Eliminating pre-machining operations is often the difference between winning bids and profitability.

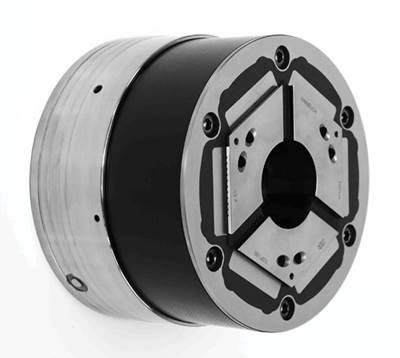

Read More“Intelligent” Chuck Regulates Clamping Force

Hainbuch is working to develop an “intelligent” chuck that monitors actual clamping forces on the workpiece and triggers necessary corrections automatically.

Read MoreThe Hidden Cost Of EDM Wire Consumption

Excessive wire consumption on a wire electrical discharge machine is costly. Technology that allows slower unspooling speeds without compromising results appears to be the answer.

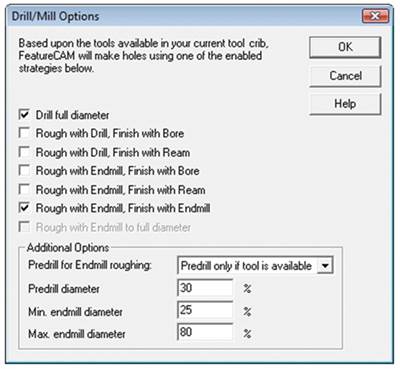

Read MoreUse The Tools That Are Available

Typically, creating holes isn’t a daunting task. However, programming, machine set up and cycle times can be prolonged when a part has numerous hole diameters. A new feature-based CAM strategy automatically determines how best to combine drilling and milling to create the holes using only the tools already loaded in a machine.

Read MoreMax-Flute Solid Carbide End Mill

(Sponsored Content) MAG’s CYCLO CUT cutting tool line introduces the Max-Flute solid carbide end mill. The Max-Flute technology delivers a step-change in machining of a broad spectrum of jet engine components in both titanium and nickel alloys. MAG’s Max-Flute was also selected the winner of the prestigious 2009 Sir Henry Royce Awards for Technical Innovation.

Read MoreCYCLO COOL Advanced Technology Fluids

(Sponsored Content) The metal manufacturing industry is dynamic and evolving toward medical and aerospace titanium machining applications. MAG’s CYCLO COOL Advance Technology Fluids are meeting the titanium machining challenges with CYCLO COOL 5000. This unique metalworking fluid exceeds conventional cutting fluid lubrication capabilities and is proven to reduce tooling cost and increase production.

Read More