Articles

The Start Point For A Custom Macro

With most user-created canned cycle applications for custom macro, you must provide a starting position from which the custom macro will begin its operation. In many cases, this leads to some redundancy in programming because the cutting tool may already be in the starting position prior to the G65 command that calls the custom macro.

Read MoreWhat Does “eAx for HMC ZzxBm_XzxYxySt” Mean?

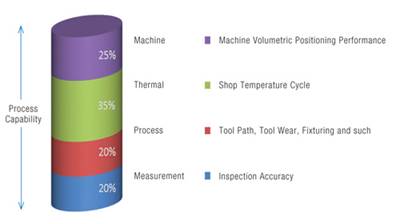

Although "eAx for HMC ZzxBm_XzxYxySt" is an odd-looking string of letters, it is an example of precise notation for identifying sources of error in machine tool performance. The naming conventions represented by this example bring order and clarity to one company’s efforts to evaluate and improve machining results. Identifying errors correctly is essential to understanding concepts such as volumetric performance and error budgeting. Â

Read MoreThe Big Niche

Expertise and the right equipment for machining large components for oilfield and other industries enable this shop to succeed despite fluctuating economic conditions.

Read MoreWear Compensation Ensures Accurate Wheel Contours

Profile grinder manufacturer Blohm Jung's GEOID system automatically compensates for wear in diamond dressing tools. By removing variables that require operator attention, the system is said to ease wheel dressing, ensure accurate profiles and extend the service life of dressing tools. Â

Read MoreResolving Large Measurement Issues

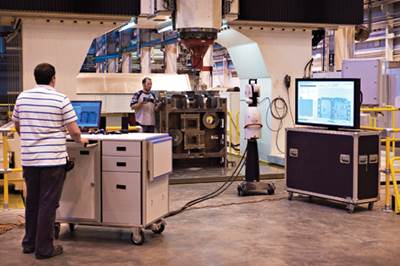

One of the world’s biggest defense contractors standardized its metrology software to open up a significant process bottleneck: measuring huge parts on a variety of equipment.

Read MoreFocus On Knowledge, Not Just Skills

"Knowledge" is the context that equips an employee to respond to new challenges.

Read MoreWhat Is The Right Machine Tool For Titanium?

Rather than start with the machine, says Boeing, start with the tooling. For titanium workpieces and other high-value parts, a simple spreadsheet of tools and operations might be the most valuable resource for machining center selection.

Read MoreCan A Machining Center Be Used As A CMM?

One manufacturer in need of a shop-rugged CMM wants to use a probe-equipped VMC for precisely this purpose. The shop asked probing expert Renishaw about this idea. Here is the response.

Read MoreHow Do You Get The Cutting Parameters Right For Small End Mills?

A reader recently asked about speed, feed rate and depth of cut when using small tools in steel.

Read MoreUsing Small End Mills In Steel Without Breaking

A reader wants to mill with small tools on a straightforward VMC used for full-sized work. MMS Online’s micromachining expert offers advice.

Read MoreWhat Lean Looks Like

A lean manufacturing consultant lists ways that lean shops look and operate differently.

Read MoreThe Most Valuable Resource For Succeeding At Lean

What is the most valuable resource? The answer is probably obvious: the people. This shop started to succeed at lean manufacturing once every employee got involved.

Read More