Articles

Seeing More For CNC Multi-Spindles

Motor technology, machine design and software possibilities all improve the economies of these sophisticated high-volume machines.

Read MoreGrinding’s Role In A Thermal Spray Shop

Cylindrical grinding is the final step in bringing worn components back to size after applying a build-up coat of molten metal.

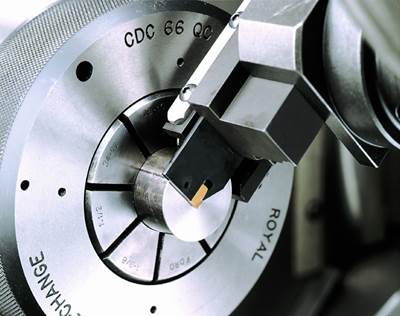

Read MoreThe Case For Quick Change On Multi-Spindles

Even in the world of long-running, high-volume production on cam-driven automatics, quick-change tooling makes sense.

Read More24-7 Coolant Monitoring And Internet Reporting

This coolant monitoring system automatically adds chemicals to maintain recommended composition. It also automatically stores coolant data and offers shops access to customized reports at a password-protected web portal.

Read MoreBar Puller Basics

Bar pullers are cost-effective alternatives to enable automated turning on CNC lathes. This article explains how they work and how shops can benefit from using them.

Read MoreAnother Step Toward CNC Programming Automation

Part designers and part programmers have to think differently. Esprit FX is a development from DP Technology (Camarillo, California) that helps overcome the "disconnect" that occurs when designers pass geometry to CNC programmers. FX stands for "feature exchange." It allows programmers using Esprit CAM software to receive information about the designer's original intent automatically so that part programs can be created more quickly and more accurately.

Read MoreRe-Designing The Reamer

This reaming system uses a multiple-cutting-edge, solid carbide cutting disc that can be changed as easily as an end mill's insert.

Read MoreLights-Out With A Lighter Commitment

For this integrated flexible pallet cell, the machines and the pallet system came from different suppliers. The shop is not locked into any supplier for adding machining centers later.

Read MoreRotational Motion Lets Turning Compete With Grinding

Rotational turning provides machined surfaces smooth enough to let turning compete with grinding and polishing.

Read MoreVirtual Machining In The Real World

Using software that models machining passes, a Cessna plant unlocks real capacity by finding better parameters for its existing NC programs.

Read MoreUnder One Roof

In bringing multiple manufacturing processes in-house, this medical shop parallels its customers' efforts to be one-stop sources for hospital equipment.

Read MoreCAM Software As A Creativity Tool

This job shop relies on its CNC programming software to unlock the productivity of its multi-axis, multi-tasking machine tools and CNC Swiss-type machines.

Read More