Columns

Random Thoughts About Reshoring and Buying American

What will be the effect of the supply chain disruptions of recent years? Here are several observations related to where companies produce and how we think about a manufactured product’s origins.

Read MoreLessons on the Journey Toward Shop Automation

By necessity, small and mid-sized American job shops are automating production, whether through swift, dramatic upgrades in capital equipment, or slow, methodical changes to processes and procedures on the shop floor.

Read MoreHelp Operators Understand Sizing Adjustments

Even when CNCs are equipped with automatic post-process gaging systems, there are always a few important adjustments that must be done manually. Don’t take operators understanding these adjustments for granted.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreWhy Towns Want Manufacturing Plants

A manufacturing facility can harness and focus the native ability of people growing up in a town, and channel this into livelihoods and homes for the town’s next generation. Is this something we lost sight of and are now seeing again?

Read MoreAdjusting CAM Tolerance and Machine Modes to Fix Faceting Issues

Fixing an issue often requires fine tuning of both CAM tolerances and the machine mode for full optimization and process reliability.

Read MoreChoosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

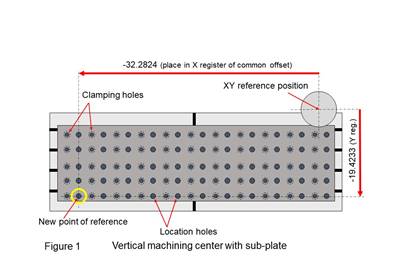

Read MoreThe Best Point of Reference for Program Zero Assignment Entries

Correctly specified program zero assignment and coordinate position values enable the CNC to determine how far to move the cutting tool during each positioning motion.

Read MoreThere's Your Waste, Shaw! An Argument for Shop Reinvestment

The fictional Don Walling had it right: Innovation and long-term success for machine shops requires investments in technology and people. Not just one, but both.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreHow to Optimize Operator Efficiency on Any Shop Floor

Striking the perfect balance of person to machine is unique to each shop and can depend on a number of factors, including the type of work a shop undertakes, the available equipment, staffing levels, scheduling and more.

Read MoreA Higbee Thread Milling Custom Macro

Higbee threads provide a full thread form at the very start of the thread. The sharp edge is removed during the machining process.

Watch