Five-Axis

Automated High-Speed Machining For Small-Part Manufacturing

The M8 is a five-axis, high speed machining center designed for manufacturing small parts, especially those requiring tight tolerances. The center can access five sides of a part to complete it in a single set-up. According to the company, the center is ideal for producing medical, aerospace and electro-mechanical components.

Read MoreShop Reduces Setup Time With Multi-Pallet Machines

Automated, lights-out production has enabled this manufacturer to take on a large number of low-volume jobs for various industries. With a wide variety of work, minimizing setup times is key to the shop’s success. Multi-pallet, four- and five-axis Matsuura machines supplied by Methods Machine Tools have enabled the shop to not only keep setup times low, but also meet customer demand for nearly error-free production runs.

Read MoreSimultaneous Five-Axis Machining

The Mikron HSM 400U is said to deliver powerful performance and precision on all five axes to produce high-quality surface finishes for demanding high-precision applications. Designed to accommodate workpieces ranging to 9. 05" × 13.

Read MoreFive-Axis CNC Center With Rotary Table

The five-axis, 5X-160 CNC machining center features a Tsudakoma trunnion five-axis rotary table. Standard features of the machine include box ways, high speed look-ahead, chip wash, spindle air blast and more. The company also offers the Cyclone-32 CS seven-axis, dual-spindle, CNC turn/mill center.

Read MoreVideo: Five-Axis Milling On Linear-Motor Machining Center

Linear motors take the place of ballscrews on this machine performing high speed cutting of aluminum at a job shop near Atlanta.

WatchVideo: Horizontal Profiler For Aerospace Machining

An alternative to the typical profiler design, this machine saves labor by allowing chips to fall out of the way.

WatchWhat Is The Right Way To Become An Aerospace Shop?

This Atlanta shop succeeded at becoming an aircraft-industry parts supplier. The lessons of its success have a lot to do with commitment and enthusiasm.

Read MoreVersatile Five-Axis Machining Center

Fryer Machine Systems offers the 5X series of five-axis machining centers. Designed for versatility, the machines combine three axes of motion with a two-axis articulating spindle. The head features a 22,000-rpm, liquid-cooled, 20-hp spindle that utilizes HSK 63 tooling.

Read MoreFive-Axis, Multi-Function Center

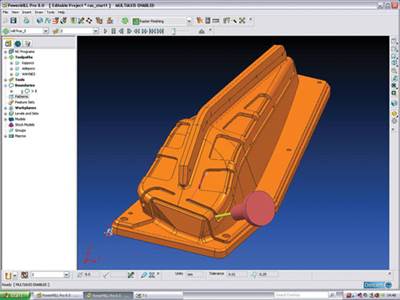

The Mi8 five-axis turning and milling center from Amada Wasino is designed for the medical, aerospace and other industries that demand parts with extreme precision. The multi-function center is suited for manufacturing complex, multi-operation workpieces, such as components for electric hybrids, hydrogen engines, new-generation diesel and gas fuel injection systems. The center integrates a tool changer and auto loader, making it ideal for the die mold industry, the company says.

Read MoreGetting New Business with Big Machines

These shops saved themselves from dependence on the declining automotive sector thanks in part to their commitment to large-scale machining capacity.

Read More