Automation

Can Vision and Artificial Intelligence Make Every Robot Collaborative?

That is the aim of this Boston-area startup. Last year, it came to market with technology to make even fast and powerful industrial robots safe to approach. The technology promises to eliminate the need for guarding around them — safety measures that might not be as safe as you think.

Read MoreMitsubishi Electric's Integrated Machine Analytics App Monitors Multiple Machines

Mitsubishi Electric Automation’s Integrated Machine Analytics (IMA) mobile application allows users to monitor their CNC machines through MTConnect, an open standard that makes universal equipment connectivity possible.

Read More3 Mindset Changes for Lights-Out CNC Machining

Expanding capacity into the unattended hours calls for counterintuitive new ways of thinking about the work.

Read MoreManufacturing Event Features Revolutions in Automation

The MT360 event will feature Cognitive Automation, the use of AI and Machine Learning to improve the capabilities of automated systems.

Read MoreIn Lights-Out Machining, Part Loading Is Not the Problem — Here is How This Shop Handles Unloading

Correct unloading of the parts affects part quality as well as the capacity of the unattended machining system. Here is more of the experience from our “168” shop.

WatchWhat is the Role of Collaborative Automation in Production?

Thyssenkrupp Bilstein’s North American operations is finding out. The shock absorber manufacturer has eight cobots and counting in its Ohio production facility, plus two autonomous vehicles. Here are scenes from its shop where the picture of automation is changing.

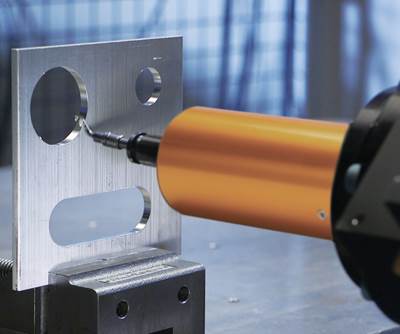

Read MoreATI Offers Deburring Blade Suitable for Automation

The pneumatically controlled, articulated design of ATI Industrial Automation’s Compliant Deburring Blade (CDB) enables users to tune the contact force to accommodate specific applications by changing the air pressure.

Read MoreRunning Unattended at Night Lets Machine Shop Serve New Customers During Day

Precision Tool Technologies found capacity for diversification not by adding machines, people or space, but by freeing up time. Running unattended—running so it can machine through all 168 hours in the week—has enabled this shop to use hours when staff is present to deliver work that lands outside its established specialty. To achieve unattended machining, some of the biggest challenges have related to basic details such as chips and coolant.

Read MoreSiemens and Comau Collaborate to Offer Sinumerik CNC Incorporating Robot Control

Through a cooperative agreement, Siemens and Comau now offer a jointly engineered Sinumerik Run MyRobot DirectControl product.

Read MoreManufacturing to Meet Tech Community at MT360

I will hold onstage conversations with additive manufacturing and collaborative automation leaders as part of the new technology event to premier May 12-14, 2020, in Santa Clara, California.

Read More