CNC Tech Talks

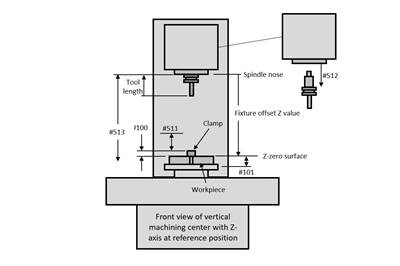

T Codes Simplify Tool Length Confirmation Process

CNC users can program custom macros and T codes to ensure cutting tools are the proper length for tool length compensation in machining centers.

Read More5 Common Mistakes When Using CNC Machines

Spend enough time on the shop floor and you will see some of the same mistakes time and again.

Read More5 Tips for Selecting the Optimal Spindle Range

Learn how to select the appropriate spindle range and ensure that your CNC machining center or turning center is running an optimized cycle.

Read More3 Ways to Improve CNC Utilization Without Sacrificing Safety

Operator safety is the most important consideration when improving CNC machine utilization.

Read MoreHow To Reference Custom Macro Variables by Name

FANUC now enables CNC users to reference custom macro system variables by names in addition to hard-to-remember numbers. Here’s how.

Read MoreG Code To Include in Your CNC Program After It Ends

There are some G-code commands you might want your operators to occasionally execute but not for every cycle. Consider these examples.

Read More4 CNC Data Transfer Methods You Should Know

Modern CNCs enable transfer and backup of more than just machining programs.

Read MoreCNC Machine Programming: Dealing with Spindle Probe Results in Real Time

There are several situations in which a CNC programmer must work with spindle probe results in the G-code program itself. Here are some strategies to consider.

Read MoreWhich Kind of "More So" Are You?

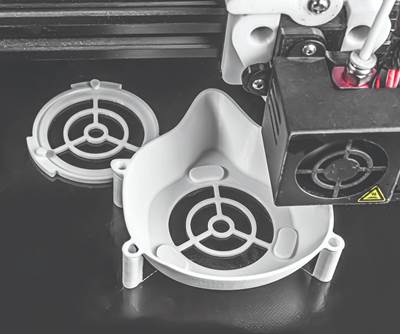

The coronavirus pandemic has brought many people, businesses and industries to a standstill. How are you reacting?

Read More4 Things to Incorporate in CAM-System-Generated CNC Programs

Streamline G-code programs created by CAM systems.

Read More