Data-Driven Manufacturing

Finally, A Comprehensive Software Solution Designed for Small Job Shops

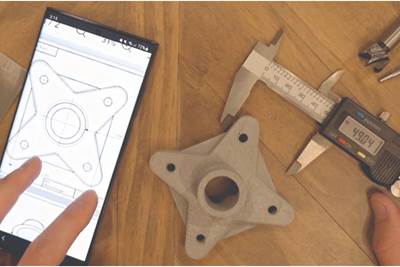

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

WatchCobot Monitoring for Universal Robots Equipment

Precision manufacturers can now monitor collaborative robots from Universal Robots in real-time to drive automation that improves performance and reliability.

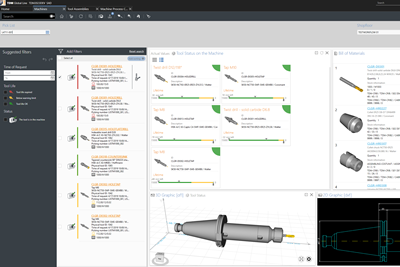

Read MoreDigital Tool Management System for Small Manufacturers

TDM Systems Inc.’s software enables the use of different communication options with production machines to implement an automated transfer of tool data directly to the machine control.

Read MoreDon't Miss This: Technology Trends

Manufacturing advances like automation and machine monitoring software are not only affordable for job shops, they may soon become competitive necessities.

Read MoreBluetooth-Enabled Digital Readout System

IMTS22: The interface of the droPWR system enables connection to multiple machine configurations in one tablet, including for milling, turning and grinding machines with up to six axes.

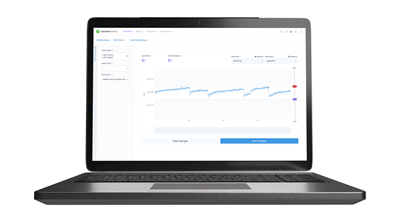

Read MoreAutomation and Connectivity Features Boost Machine Data Platform Efficacy

IMTS22: Expanded features from MachineMetrics are intended to enable manufacturers to drive frontline worker productivity and factory systems with real-time machine data.

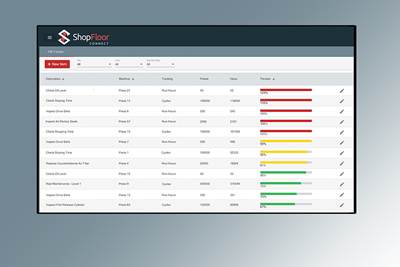

Read MoreData Collection Software Increases Efficiency, Reduces Downtime

IMTS22: Wintriss Controls Group’s upgraded ShopFloorConnect identifies and quantifies excessive production losses and bottlenecks.

Read MorePredictive Maintenance Software Offers Real-Time Visibility

IMTS22: Vimana’s predictive maintenance software collects and transforms large volumes of data from multiple sources, including sensors, machine data, manufacturing and IT systems.

Read MoreAutomated Production Intelligence Streamlines Monitoring

IMTS22: Datanomix’s Automated Production Intelligence platform provides automated job performance data for every single part made on every machine, with no configuration.

Read MoreHow Manufacturing Data Can Save the World

Digital spaces rooted in real-world sensor data help scale big ideas and move humanity toward a more sustainable, autonomous future.

Read More