Machines

Edge Technology Sliding-Headstock Lathe Boosts RPM

The FMB Turbo 3-38 for sliding-headstock CNC lathes provides superior bar pushing and stock support in the transition zone between the bar feeder and lathe spindle.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreANCA Grinding Solution Provides Flexible Five-Axis Machining

The TX7 Linear and TXcell Linear provide flexibility in the applications that can be put through it than other three-axis grinders more traditionally used for punch manufacturing.

Read MoreControlling Extreme Cutting Conditions in Large-Part Machining

Newly patented technologies for controlling chatter and vibration during milling, turning and boring operations promise to drastically reduce production time and increase machining performance.

Read MoreHermle Event Encourages, Educates on Five-Axis Machining

Hermle’s first Five-Axis Summit was designed to show beginners the benefits of five-axis machining and demonstrated how more advanced users can take their capabilities to the next level with automation.

Read MoreThe Keys to Combining High- and Low-Volume Production

Process expertise and precise production planning enable the Kinetic Company to produce both high- and low-volume jobs requiring machining, grinding, heat treatment and other processes.

Read MoreFryer’s Horizontal Boring Mill Designed for Ease of Use

The HB Series Boring Mills feature rugged cast iron bodies and high-precision ballscrews and bearings to ensure high-accuracy tolerances.

Read MoreQ&A: How a Self-Taught Machinist Started His Own Business

This machinist found an opportunity in a niche market and decided to learn machining and create his own business. Here's how he did it.

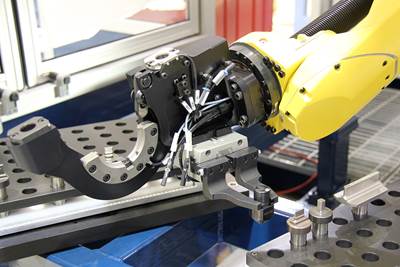

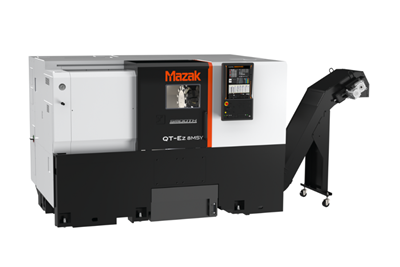

Read MoreMazak Horizontal Turning Center Enables Versatile Machining

The QT-Ez 8MSY horizontal turning machine integrates seamlessly with bar feeders and robots, and accepts many additional options to tailor it to the needs of any shop.

Read MoreSteady Culture, Flexible Plans Enable Custom Tooling Success

By late 2019, West Ohio Tool’s client list only spanned one page. The company overhauled its culture and is now on track for its most successful year ever.

Read More