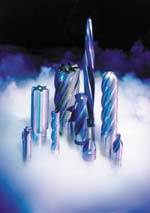

Milling Tools

Milling System Puts Productivity In Fast Lane

When this company won a contract to machine automotive parts for a customer, they were faced with the need for a milling tool that could meet tighter cycle times, enable machining centers to perform multiple tasks, maximize the life of milling tools and reduce tool inventory.

Read MoreUsing Helical Interpolation To Make Large-Diameter Holes

Producing a large-diameter hole is a common application for many shops, and there are numerous methods that can be used to achieve the end result. However, there are often numerous obstacles to completing the process cost effectively.

Read MoreBringing Cryogenics In From The Cold

There are numerous cases of significantly improved performance from steel and carbide cutting tools that have undergone cryogenic (deep freeze) treatment. But wide use of the process seems to suffer from a perceived lack of scientific underpinnings.

Read MoreTools For Milling In Z

The fastest way to mill away a lot of material may be to attack it head on with a move in the Z direction.

Read MoreSmall Milling Tool Accounts For Big Productivity Gain In Machining Forging Dies

Who would have ever thought that such a small mill could so consistently and so reliably finish machine that hardened die steel.

Read MoreWinner By A Nose!

Wiper technology is designed to improve surface finish in machining applications. It involves an insert with a flat. As the 'wiper' passes through the cut, it smoothes the surface.

Read MoreVacuum Pump Maker Finds Innovative Ways To Reduce Manufaturing Costs

With new tooling, this manufacturer was able to mill housings at 3,000 sfm and a feed rate of 230 ipm. Cutting time dropped from 20.68 minutes to 12.74 minutes, a savings of nearly 40 percent.

Read MoreTrends That Drive Cutting Tool Development

Cutting tools have highly engineered coatings and geometries for all types of manufacturing methods and materials.

Read MoreDon't Touch That Tool

Tool measurement is critical to the metalcutting process. Exact knowledge of a cutter’s length, diameter, even profile, and the ability to measure and monitor these dimensions over time, can reduce variability and help optimize the process. Here’s a look at how non-contact tool measurement and breakage detection benefit your metalcutting process.

Read MoreAerospace On A Diet

The difficulty of close tolerance finishing in both high temperature alloys and titanium is particularly real in the Aerospace industry, where thinwall construction is becoming more common. Read how an insert gave this shop an edge.

Read More