Tooling

Video Highlights Extreme Part-Off Demos

The strength of a tough part-off tool is shown in video showing it parting off a railroad rail and sledgehammer head. Talk about significant interrupted cuts…

WatchVideo: Re-Use Soft Jaws with Expanding Pins

When tool-and-die and contract machine shop Baklund R&D developed a workholding device to solve a challenge with one of its own jobs, the company realized it potentially had a solution that could benefit many other shops as well.

WatchRigid Spindle Interface with Tool-Locking Technology

Kennametal and Haimer have developed the KM4X spindle interface with Safe-Lock toolholder technology.

Read MoreModular Interface for Cutting Tool Heads

Haimer and Kennametal introduce the new modular Duo-Lock interface for carbide cutting tool heads.

Read MoreAn Extreme Part-Off Demo Returns to IMTS 2014

The strength of part-off tools is shown in demonstrations whereby they part off a railroad rail and sledge hammer head. Talk about significant interrupted cuts…

WatchTap's Multi-Layered Coating Reduces Friction, Heat

Emuge's Z-Tap line is designed with an advanced chamfer geometry and rake/flute form for use with stainless steel, high-strength alloys, tool steels and cast steels of 30 HRc and below.

Read MoreQuick-Change Chuck Maintains Accuracy

The Quick-Jaw-Change (QJC) power chuck from Samchully Workholding is suitable for both large and small-batch production in job shops with frequent part change-overs.

Read MoreCombination Chuck Enables Off-Machine Presetting

The Gripfast Combination Power Chuck from Pratt Burnerd International, a division of 600 UK, provides lathes with a chuck, collet chuck and mandrel chuck in a single unit, available in sizes ranging from 165 to 800 mm.

Read MoreTooling Selection Keeps Big Aerospace Component In-House

Attention to the tool-up process enabled JWF Industries to launch a large-scale defense industry radar frame project, keeping production in-house and ultimately shaving weeks off of the expected production time.

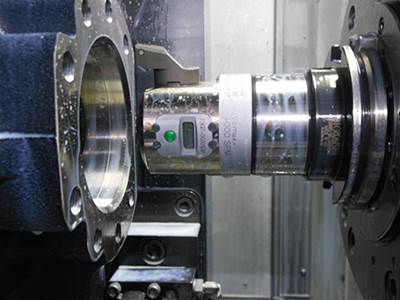

Read MoreDigital Tooling Improves Accuracy, Reduces Scrap

By switching to digital boring heads, Impact CNC was able to reduce its scrap rate while increasing precision.

Read More