Tooling

Compact, High Speed Rotary Tables

Tsudakoma TN-101, TN-131, TN-161 and TN-201 compact, high speed, tilting rotary tables from Koma Precision use a dual taper, double-disc braking mechanism, which generates massive clamp torque—an increase of 320 percent when compared to previous models. The one-piece monoblock frame construction permits maximum rigidity. The tables feature an indexing and tilting repeatability of ±2 arcseconds and are available with a full range of options including rotary scales and various chucks and collets.

Read MoreFace Driver Cuts Large-Sized Workpieces

The Neidlein FSB 75 face driver from LMC Workholding is used to efficiently cut large-sized workpieces. The face driver is able to make heavy cuts on large barstock and forged workpieces up to 12 ft. long, 28″ in diameter and weighing as much as 13,000 lbs.

Read MoreMulti-Purpose Tool Performs 8 Operations

With one multi-purpose tool, Magafor says it can increase production, cost savings and quality. The Multi-V multi-function carbide tool is capable of performing eight separate operations—centering/spotting, V-grooving, engraving, counter sinking, interpolation drilling, chamfering and longitudinal chamfers. The multi-function tool can meet diameter needs ranging from 0.

Read MoreInserts For Aggressive Metalcutting

High-performance CNC-pressed Toroid inserts from Dapra are designed for aggressive metalcutting and long tool life. These thicker inserts offer enhanced heat absorption capabilities and feature a stronger cutting edge for heavier chip loads and greater shock absorption. Additionally, positive top rake results in reduced cutting forces and lower torque.

Read MoreVariable Rake End Mills

SGS Tool Company’s Z-Carb-AP variable rake end mill offers three stages of chatter suppression resulting in a quiet, stable milling operation. In stage one, unequal flute spacing disrupts the rhythmic pattern created by the cutting edge of common end mills. This suppresses the development of damaging harmonics.

Read MoreRing Groove Cutter Line

Designed specifically for the oil and gas industry, Greenleaf Corporation’s expanded Ring Max line of ring groove tooling is suited for difficult to machine materials. Combined with the company’s WG-300 or WG-600 whisker-reinforced ceramic inserts, the ring groove cutters can reduce cutting times from 30 min. to less than 1 min.

Read MoreDrill Point Grinders

Cuttermasters’ GSC drill point grinders are designed to regrind drills with diameters ranging from 0. 098 to 1. 032".

Read MoreLathe Toolholders For Efficient Coolant Use

Streamliner lathe toolholders feature coolant delivery through the shank and are said to be suited for low- or high-pressure delivery. To conserve coolant, the toolholders are equipped with interchangeable coolant-distribution plates for various volumes of air, mist or liquid. The coolant delivery is parallel to the top of the insert, which enables the coolant to have a positive effect at the shear zone.

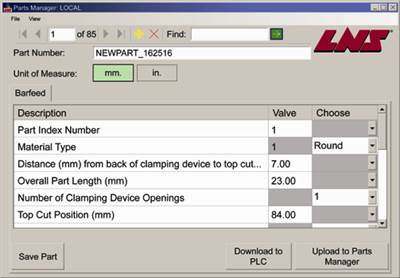

Read MoreLathe and Feeder Talk Via Ethernet Interface

Research into the connectivity and communication between machine tools and equipment like bar feeders, part unloaders, pallet systems and even high-pressure coolant systems is yielding useful ability on the shop floor. In this case, LNS uses Internet technology in its S65 bar feeder to communicate with a PC-based Fanuc CNC running a Mori-Seiki NZ2000 lathe.

Read MoreAdjustable Drill Drives Inventory Cost Savings

During a difficult application, the inserts on this shop’s standard IC drill would sporadically fail, causing the entire tool to break down. This required the shop to stock a large inventory of costly replacements in various sizes to fit different-sized holes. Allied Machine and Engineering’s Revolution drill allows the shop to adjust tool diameter and cut holes of different sizes with a single tool, while replaceable insert cartridges on the front end keep insert failure from wrecking the tool itself.

Read More