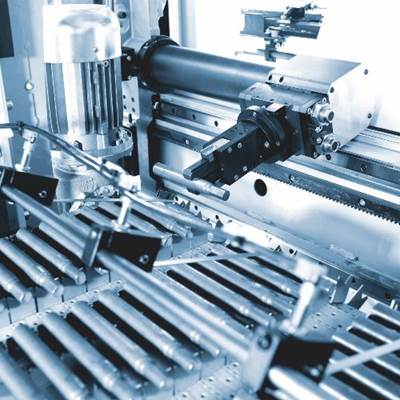

Turning Machines

Space-Efficient Automation for CNC Lathes

Loader moves entirely within the footprint of the machine.

Read MoreAutomation at Aztalan Engineering

A contract manufacturer expands its capacity using various approaches to feeding the machines.

Read MoreVertical CNC Lathe Integrates with Factory Automation

The Hwacheon VT-650 vertical CNC lathe provides a maximum cutting diameter of 31.44" and features a 1,500-rpm spindle drive.

Read MoreCNC Automatic Lathe for Precision Parts

Marubeni’s R07 Cincom sliding-headstock-type CNC lathe offers a maximum machining diameter of 7 mm.

Read MoreLarge-Bore Lathe Handles Rough and Fine Turning

Chevalier’s FB-510MC slant-bed lathe is designed for pipe-threading applications required by gas, oil and related industries.

Read MoreVertical Turning Lathe for Large, Heavy Parts

Methods Machine Tools’ high-performance Feeler FVT-600 vertical turning lathe is designed for machining large, heavy parts such as those used in the aerospace and power-generation industries.

Read MoreCNC Turning Center Provides Cutting Flexibility

The Goodway GS-6000 series turning center, available from Yama Seiki, combines a high-rigidity boxway bed with large-diameter servo indexing turret and a two-step gear-spindle structure.

Read MoreHeavy-duty Horizontal Turning Center

The Hwacheon Hi-TECH 450 turning center with its small footprint provides space efficiency, while offering the largest turning diameter in its class of mid-size lathes at 500mm as well as turning length of 1350 mm, according to the company.

Read MoreHorizontal Turning Center for Oil and Gas Applications

The Hwacheon Hi-Tech 450 horizontal turning center offers a 500-mm turning diameter and 1,350-mm turning length in a small footprint.

Read MoreGang-Tool Turning Center for Medical Applications

The Hardinge Quest Super-Precision GT27 gang-tool turning center is designed for machining small diameters and tight-tolerance parts, such as those required for medical devices.

Read More