Vertical Machining Centers

California Shop Reduces Cycle Times, Increases Productivity

In order to survive in today's competitive marketplace, small job shops must find ways to cut costs and increase productivity--all without sacrificing quality.

Read MoreIt's Within Your Grasp -- It Will Extend Your Reach

Though high speed machining means different things to different people, all of the diverse applications of this process involve performing operations fast enough to break into a new realm of possibilities.

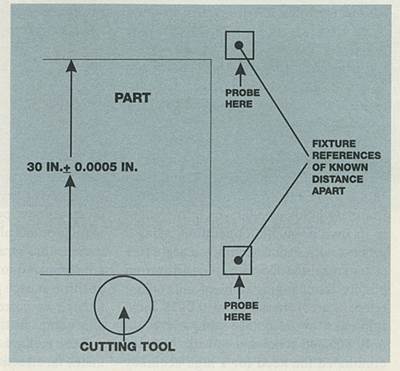

Read MoreBreak The Accuracy Barrier

"Reference comparison" uses probing to hold accuracies tighter than inherent process error.

Read MoreOne-Man Machine Shop Has Flexibility For Parts Many Shops Pass Up

Some of the most difficult parts for Boeing Aircraft are made not in a factory, but in a one-man machine shop located down a country lane, 23 miles south of Tacoma, Washington.

Read MoreVertical Machining Center Reduces Cycle Time By 84 Percent

A certified subcontractor to Xerox, Space Labs, Barry Controls, ITT, Pacific Scientific, and Air Bus Industries, this shop's parts aren't required to be inspected. Parts are shipped directly from the job shop to the customer's production line.

Read MoreLow Cost Machine - High Efficiency Machining

This captive machine shop gets extremely high utilization of their vertical machining centers through clever workholding and handling procedures.

Read MoreManufacturer Increases Productivity More Than 300 Percent With CNC

Mac Stripers wants to leave its mark on the world. After ten years in business, the manufacturer of road-striping equipment reports $2 million in sales and is looking to double its 12,000 square-foot facility.

Read MoreAerospace Lathe Shop Finds VMCs Enhance Commercial Work

There's no trick to reducing cycle time. It's simply a matter of knowing what tools to use for which parts.

Read MoreCustomer-Dedicated Machining Cells To Assure Quality And Commitments

Kenlee Precision Corp. began operations in Baltimore as a general practice job shop in 1969. The business was started on the typical shoestring, with some borrowed capital, a few machine tools and plenty of moxie on the part of President/ Owner Ken Lewis.

Read MoreA Highly Evolved Fab Shop

In today's manufacturing environment, it's survival of the fittest. This fab shop found that an automated fabricating cell was a natural selection. Continuing this process of evolution, a new species of job shop may emerge.

Read More