Workholding

Automation Helps Move To High-Volume Production

This tool manufacturer had to automate its processes after switching from low-volume special orders to high-volume production runs. Since implementing Tsudakoma tilting rotary tables along with robotics and a pallet conveyor, the shop has increased sales by 400 percent.

Read MoreModular Fixturing System

The Demmeler modular fixturing system from Bluco features accurate five-sided welding tables made of high-tensile-strength steel. Angles, spacer blocks, clamps, positioning and clamping bolts and universal stops can be assembled into a ready-to-use welding fixture in a matter of hours, the company says. The system is said to be ideal for prototypes, spares and other short-run jobs, the company says.

Read MoreFourth Axis Reduces Part Cycle Times

The FANUC DDR/B from Methods Machine Tools is a rotary fourth axis designed specifically to complement the speed and versatility of the FANUC RoboDrill VMC. By eliminating the positioning delays of traditional rotary tables, it reduces part cycle times. The fourth axis can unclamp, rotate 180 degrees and reclamp in less than 0.

Read MoreCNC Rotary Table Features Carbide Worm System

The 5AX-200II CNC rotary table from Lyndex-Nikken is said to perform with high accuracy and fast rotating and tilting speeds. The company’s patented carbide worm system ensures wear resistance, rigidity and the rapid speeds of this rotary table. The carbide worm system uses a carbide worm screw and ion nitrided worm wheel rather than a conventional bronze or bronze-alloy actuation mechanism.

Read MoreHydraulic Workholding Doubles Output

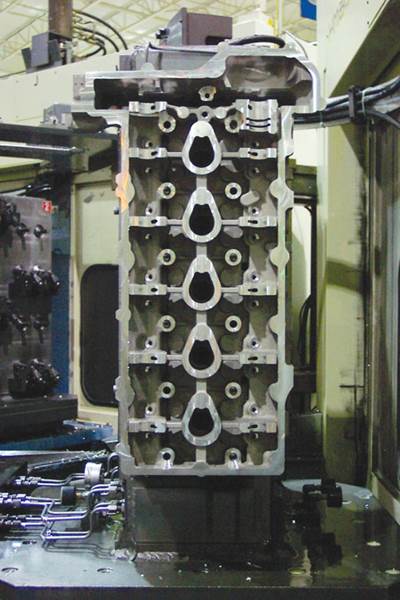

When customer-supplied fixtures just weren’t cutting it, this automotive shop turned to Advanced Machine & Engineering for dedicated, hydraulic tombstones to use on its high-volume production runs. The new fixtures have since reduced load/unload time, cycle time and scrap rates while providing error-free loading.

Read MoreVise Jaws Carry Shop To New Levels Of Productivity

This shop used carrier workholding, in which the workpiece is gripped by a thin layer of extra material, to reduce cycle times. However, the cost of the carrier material and the time taken to remove it sometimes outweighed any cycle time improvements. Vise jaws from Talon Grip Systems that can grip as little as 0.06 inch of material allowed the shop to reduce carrier sizes and fully realize the benefits of this workholding method.

Read MoreBar Feeders Feature Five-Year Warranty

IEMCA announces that its bar feeders are now backed by a five-year warranty. The five-year warranty, available for a limited time, covers all parts and labor for the first year of ownership and the cost of parts for the next four years. The warranty does not affect machine pricing, and is automatically included wit

Read MoreFlexible Flat Plate Pod

The Nemi flat plate vacuum slider pod base features the flexibility of flat plate pod location and placement, while maintaining the versatility of interchangeable tops. The vacuum pods can be configured for individual use as well as daisy chaining. All pods are equipped with 8-mm fittings unless otherwise specified

Read MoreHydraulic Workholding Devices Allow Total-Perimeter Machining

Having access to the entire perimeter of a part minimizes set ups because shops can machine five sides of the part in one fixturing. This enables shops to reduce the total number of manufacturing operations, the number of times parts must be handled, the potential for part damage due to excessive handling and the o

Read MoreRotary, Index Tables Designed For Precision Machining Applications

Featuring photos, specifications and detailed diagrams, this catalog details Tanshing’s line of CNC rotary tables and index tables. The tables are equipped with the company’s dual lead worm drive system, which is said to provide rigidity, transmission torque and wear resistance during machining. Models are availabl

Read More