CGTech

9000 Research Dr.

Irvine, CA 92618 US

949-753-1050

info@cgtech.com

CONNECT

About CGTech

CGTech specializes in NC/CNC simulation, verification, optimization, and analysis software for manufacturing. Since 1988 CGTech’s product, VERICUT® software, has become the industry standard for simulating CNC machining in order to detect errors, potential collisions, or areas of inefficiency.

IS THIS YOUR COMPANY?

As Seen On 91ÊÓƵÍøÕ¾ÎÛ

CGTech Supplies the Following Products

- CAD/CAM for Additive Manufacturing

- CAD/CAM Software

- CNC Software, Stand-alone

- Engineering Analysis & Simulation

- Job & File Management Software

- Machinability Databases

- NC Program Optimization

- NC Verification

- Post Processors, Stand-Alone

- Software, Other Manufacturing

- Tool Design

- Training

Trade Names Offered by CGTech

Editorial, News, and Products

-

Advanced Tool Paths, Simple Implementation

Programming advanced tool paths used to be a complex, time-consuming task. Canned cycles in CAM software have now made them more accessible than ever.

-

Vericut AI-Powered Tools Enhance Software Accessibility

Vericut Intelligence and Vericut Assistant aim to simplify the way users can interact with and gain knowledge from Vericut’s software products.

-

Refining Shopfloor Processes for Mission-Critical Parts

Pacon Mfg, Inc. has not rested on its laurels as the 2020 Top Shop Honoree for Shopfloor Practices and Performance. In the years since, it has refined its processes to continue excelling in a volatile market.

-

CGTech Software Update Features Interactive Capabilities

CGTech releases version 9.5 of its independent Vericut software, designed with a custom tool summary, heat display, interactive simulation timeline and more.

-

CGTech Announces Partnership With 3DCAD

The partnership aims to extend the simulation, validation and enhancement capabilities of Vericut to a wider range of organizations in Mexico.

-

Multitasking Machines Cut Days From Shop’s Setups

Adopting WFL Millturn machines enabled BWXT to condense operations and setups while also providing a simple way to simulate and secure processes.

-

Simulation and Tooling Secure High-Value Work

Simulation software and careful attention to tooling parameters have enabled Major Tool to take on ambitious projects with its complex machinery.

-

CGTech Simulation Software Optimizes Machining Operations

Eastec 2023: Vericut detects errors and potential collisions in NC programs prior to running them on machines for the first time, so programmers can send programs to a machine with the confidence that they’ll run without incident.

-

Vericut 9.3 Features Upgraded Connectivity

Vericut 9.3 aims to create more efficient manufacturing processes with features that bring in data around the machine, the tools and the stock to improve simulation and the overall manufacturing workflow.

-

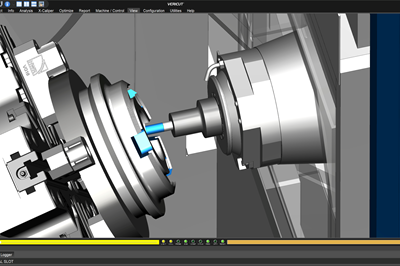

CGTech Demonstrates Vericut 9.3

The latest version of CNC simulation software incorporates improvements and new features focusing on using data for more informed manufacturing.

-

CNC Simulation Software Uses Data for Smarter Manufacturing

The latest version of CNC simulation software incorporates enhancements and new features focusing on using data for smarter, more informed manufacturing.

-

Digital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

-

ICAM to be Acquired by Sandvik Coromant

ICAM’s software combines post-processing, machine simulation and tool-path optimization into solutions that are said to save programming and part machining time. The acquisition is expected to close during the fourth quarter of 2021.

-

Vericut’s Version 9.2 Features More Optimization Options

Simulation software verifies key additive functions and makes it easy to identify errors, excessive material overhangs, voids and misplaced material.

-

Simulation Saves Money When Machining Expensive Parts

Jobs machining expensive materials mean Keselowski Advanced Manufacturing needs to be extremely cautious. The operations manager says Vericut not only prevents mistakes, it shortens cycle times.

-

CNC Optimization Software Reduces Cycle Times 25% or More and Can Double Tool Life

CGTech’s VERICUT Force optimization software can drastically reduce cycle times from 20-70%, even on supposedly optimized programs from CAM systems. It varies the feed rate to keep chip thickness and cutter load constant, which can increase tool life by 100% or more.

-

Vericut Update Improves Productivity and Sustainability

Vericut 9.2 includes several new features that boost manufacturing efficiency, help preserve machines and cutting tools, increase machine capacity and dramatically reduce repair and scrap costs.

-

CGTech Releases CNC Software Update

Company's Vericut software version 9.2 includes collision and performance improvements, new optimization and reporting features and more

-

CGTech Adds GDML Interface for Vericut

The 3DLive interface from CGTech enables Vericut software to read geometry description markup language (GDML) files.

-

CGTech To Digitally Host 2021 Vericut Vue Events

CGTech will host its free 2021 Vericut Users’ Exchange events digitally in 2021, starting on March 16 and running through the end of April.

-

CGTech's OptiPath and Force Modules Prove Complementary

The OptiPath and Force modules of CGTech’s Vericut software have improved programming and cycle times at Ultra Machining Company.

-

Simulation Gets Real

Capability to generate something close to a true digital twin can significantly improve confidence in CAM program prove-outs.

-

Sandvik Acquiring CGTech

Sandvik has signed a deal to acquire VERICUT developers CGTech, enhancing Sandvik’s ability to provide full machining solutions and increase its value proposition.

-

CGTech's Vericut 9.1 Improves CNC Simulation Visibility Options

Version 9.1 of CGTech’s Vericut includes enhancements to toolpath optimization, additive manufacturing, tooling and multi-tool stations, and measuring and inspection.

-

Aerospace Shop Adopts NC Optimization as a Means of Continuous Improvement

Steelville Manufacturing adopted CGTech’s Vericut NC verification software to safeguard its high-volume/high-mix work, but found unexpected benefits from its Force Optimization module.

-

Vericut 9.0 Features New Graphics Engine for Easier CAM Verification

Version 9.0 of Vericut from CGTech is described as “smarter” than previous versions, offering more robust connections to tooling databases and CAM systems.

-

Vericut 9.0 Enables Panning, Zooming While Cutting

Westec 2019: CG Tech’s Vericut v9.0 simulates real NC data on digital twin machines to prevent crashes, identify conflicts between setups and tooling, and ensure machined parts match engineering designs.

-

Automating Small NC Programming Tasks Pays Off Big Over Time

What started as a few Java macros the programmer whipped up to make life easier has grown to a shop-wide file management system integrated into other software, such as Vericut.

-

CGTech Plans 26 North American Vericut User Events

At VUE events, attendees learn about new software features, tips and tricks for improving manufacturing efficiency, and express ideas about future designs.

-

Software Module Optimizes Turning Programs

CGTech has announced that its latest release of Vericut 8.2, includes a new module for NC program optimization: Force Turning.

-

BeAM Applying CGTech's AM Verification Technology

BeAM, a manufacturer of powder-based directed energy deposition (DED) technology based in Cincinnati, Ohio, is partnering with CGTech to use its Vericut toolpath-simulation software’s Additive module in its equipment.

-

Test Drive Simulation for Subtractive and Additive Manufacturing with CGTech

CGTech demonstrates new capabilities in its Vericut 8.2 software including Force Turning and deposition-based additive manufacturing.

-

CNC Simulation Software Adds Convenience, AM Features

CGTech has released the Vericut Versions 8.2 CNC Simulation Software.

-

Software Performs CNC Simulation Plus Physics-Based Optimization

IMTS 2018: Version 8.2 of CGTech’s Vericut optimization and verification software simulates all types of CNC machining.

-

Machining Parts for the World’s Largest Digital Camera

SLAC is building the world’s largest digital camera, to be installed inside the Large Synoptic Survey Telescope. Getting there requires the machining expertise of shops like Keller Technology.

-

CGTech Opens Marketing and Support Office in Russia

CGTech has formed a direct office in Russia.

-

Manufacturing News of Note: May 2018

Mahr to offer confocal microscopes, CGTech joins an R&D outfit and other industry news.

-

Oregon R&D Facility Adds CGTech, Summit to Membership

The two companies will help the Oregon Manufacturing Innovation Center Research and Development develop advanced metals manufacturing technologies.

-

Shop's Coding Solution Results in New Time-Saving Software Feature

For Ultra Machining Co., manually altering Vericut’s optimized tool paths at the machine was time-consuming and risky to the part. A custom macro alleviating this is now a feature of the software.

-

CGTech Celebrates 30th Anniversary

The maker of Vericut was founded 30 years ago to provide software that verifies NC tool paths without using machine time to make a prove-out part.

-

Simulation, Optimization Software Reduces Scrap Loss, Rework

CGTech has released version 8.1.2 of its Vericut CNC machine simulation and optimization software.

-

Shop Hits Home Run with Toolpath Simulation Software

Wolcott Design Services needed to improve efficiency during high-mix, low-volume runs. HMCs and Vericut tool simulation software by CGTech improved efficiency, spindle utilization and revenue.

-

Simulation Software Helps Programmers Evaluate Method Efficiency

Version 8.1 of CGTech’s Vericut CNC machine simulation, verification and optimization software simulates all types of CNC machining, additive and hybrid manufacturing processes.

-

Verification Software Leverages Cloud for Tool Data

CGTech and MachiningCloud have jointly announced a MachiningCloud enhancement that enables Vericut users to import tool manufacturers’ cutting parameters from MachiningCloud directly into Vericut.

-

Manufacturer Sets Its Sights on Toolpath Simulation

When machining capacity and part complexity had grown to the point that simulation became necessary, Trijicon Inc. used Vericut software to reduce downtime while increasing production levels.

-

Verification, Simulation Reduce CNC Machine Crashes

Increasingly complex parts led to more crashes and longer setup times at Phoenix Manufacturing Inc. Vericut software from CGTech improved product quality and increased shopfloor efficiency.

-

Simulation Software Enables Direct Download of OEM Tool Geometries

CGTech and MachiningCloud have jointly introduced a feature that enables users to import an entire tooling package into Vericut 7.4.

-

Software Reduces Crashes on New Manufacturing Equipment

Despite new technology investments, Micro-Mechanics Holdings was still experiencing high software crash potential. Switching to CGTech's Vericut NC verification software resulted in increased efficiency and enabled crash-free, lights-out operation.

-

United Technologies Optimization Tool Added to Vericut

The new feed rate optimization tool is based on machining trials within UTC. The commitment of an established software company will help this OEM bring cost-saving technology to its suppliers.

-

G-Code Simulation Ensures Precise Machining of Large Parts

Elliott Group implemented Vericut machine simulation software from CGTech and eliminated scrapped parts due to programming errors. It also helped improve employee safety.

-

Dispelling Five Myths about Hiring Workers with Disabilities

Manufacturers seeking skilled workers should rid themselves of the misconceptions many hold about hiring disabled individuals, especially those with specialized industrial training.

-

Searching for Skilled Workers? Here’s Part of the Solution

In recent years, manufacturers have found it increasingly difficult to find trained, skilled employees, especially in the metalworking industry.

-

New Users Are Adopting Simulation Software

Even though the market for NC simulation software is mature, that doesn’t mean that new users cannot adopt it. In fact, one CGTech representative lists four reasons why shops that had never considered simulation software before are now opting for it.

-

Cutting Tool Database Interfaces with Simulation Software

CGTech now offers an interface to Zoller’s TMS Tools Management Solutions database that enables easy transfer of cutting tool information to the company’s Vericut software.

-

Vector Programming Eases Five-Axis Aerospace Machining

Because the CNCs on this shop’s largest five-axis machining centers accept vector coordinates as program input instead of traditional G codes, critical jobs can be shifted readily from machine to machine.

-

When CAM-Integrated Simulation Isn’t Enough

Whereas this shop’s CAM system is limited to evaluating only internal CAM files, Vericut software from CGTech uses the actual post-processed G code.

-

CNC Simulation Software Update Improves Speed

Version 7.2 of CGTech’s Vericut CNC machine simulation and optimization software features enhancements designed to improve speed.

-

Simulation Software Saves Time, Boosts Confidence

Vericut simulation software from CGTech provides the confidence the company needs to machine high-value parts without the time required for manual prove-outs or the risks associated with less-robust alternatives.

-

Composite Applications Simulate Fiber-Placement Machinery

Version 7.1 of CGTech’s Vericut Composite Programming (VCP) and Vericut Composite Simulation (VCS) applications are designed to program and simulate automated fiber-placement machinery from various machine tool builders.

-

CNC Machine Simulation and Optimization Software

The company’s CNC machine simulation, verification and optimization software eliminates manual prove-out of NC programs, thus reducing scrap and rework.

-

CNC Machine Simulation, Optimization Software Update

CGTech’s Vericut 7.1 CNC machine simulation and optimization software enables users to reduce scrap loss and rework by eliminating manual prove-out of NC programs.

-

Optimized Code for CNC Machine Simulation Software

Vericut 7.0 CNC machine simulation, verification and optimization software features significant performance-improving enhancements that reduce the time required for manufacturing engineers to develop, analyze, inspect and document the CNC programming and machining process.

-

Learn What More Your Software Can Do

Consider a software audit involving the software company’s support personnel. Let them watch how you use (and don’t use) the capabilities of the product you already own.

-

Tool Certainty

For GKN Aerospace to overcome tool-related variations on its largest milling machines, it had to confront error sources that go unnoticed in many shops.

-

Software Streamlines First-Part Prove-outs

On-machine part prove-outs can increase costs by tying up valuable manufacturing time and increasing the risk of errors that can damage both the workpiece and the machine itself. With Vericut simulation software from CGTech, this aerospace manufacturer has not only avoided these issues, but also increased confidence to the point where it commonly uses its multi-spindle machines to cut multiple first-run parts simultaneously.

-

Finishing A Pocket Floor In Titanium

Machining animation from Boeing illustrates effective techniques for titanium workpieces. This simulation also shows finishing of the floor of the pocket.

-

Finishing Walls In Titanium

Machining animation from Boeing illustrates effective techniques for titanium workpieces. This video shows material machined out of the corners prior to finishing.

-

Plunge-And-Sweep For Finishing Corners

Machining animation from Boeing illustrates effective techniques for titanium workpieces.

-

Applying A High Speed Machining Discipline Without The Speed

In this shop, high speed machining makes sense at 4,000 rpm. While the disciplines the shop put in place made a new 15,000-rpm profiler dramatically more productive, high speed machining would have remained valuable even if the new machine never came. Acoording to a co-owner of this shop, high speed machining has no need for speed.

-

Simulation Software Enables "Lights-Out" Five-Axis Machining

Hall & Stavert has been manufacturing marine hardware for more than 65 years. The company incorporated Vericut machine-simulation software to verify NC programs and shorten turnaround time. Developed by CGTech, the solids-based software system interactively simulates the material-removal process of an NC program. The software depicts three- to five-axis milling/drilling and wire EDM operations as well as multi-axis turning and mill/turn machining.

-

Simulation Speeds Cycle Times On Complex Parts

Selecting "safe" feed rates resulted in wasted time or poor cutting conditions on complex fuel-control parts. With optimization software, this shop achieved more aggressive feed rates.

-

Program Prove-Out Via Machine Simulation

Before new machining jobs are run at this aerospace composites facility, they are first proven out using 3D machine tool simulation software. Such preventive measures have proven valuable in eliminating damage to tools, machines and parts.

-

Simulation Software Keeps Tool Maker On Cutting Edge

As a supplier of metal-removal tooling for more than 100 years, Ingersoll Cutting Tool Company (Rockford, Illinois) has sought to help manufacturers remain competitive by providing innovative and productive metal-removal solutions. Since the early 1990s, the company has used Vericut software from CGTech (Irvine, California) as a component of its manufacturing process.

-

Software Gets Solar Racecar Up And Running

The molds needed for this racing project required 36 hours of machining time, so the team also enlisted the help of Vericut software from CGTech. Incorporating this software, the Cincinnati machine tool used didn't miss a minute of regular production time.

-

Boat Parts Production Is More Precise With Five-Axis Machining Software

With Mastercam and Vericut CNC simulation software, this company was able to produce even the tightest of tolerances for its demanding boat parts.

-

Smarter Machining Squeezes More Productivity And Profits From The Shop Floor

To increase efficiency and productivity, this Canadian mold shop began programming NC cutter paths on the shop floor, in real time.

-

Setting The Stage For Production

This software is an external verification/optimization tool that provides faithful representations of first-run machining processes. This affords the opportunity to rectify machining conflicts before the first chip flies.

-

The Case For Verifying And Optimizing Tool Paths

Two very different shops illustrate the potential value of software that works between the CAM software and the CNC.

-

The Right Tool, Right Away

In-house custom tool grinding extends the reach of CNC machining.