CNC & Machine Controls

Four-Axis CNC Controller

The Turbo Clipper Power Stack combines the intelligence and capability of the Clipper multi-axis controller with a four-axis, low-voltage amplifier and breakout system.

Read MoreDevice Rejuvenates Legacy Control System

An old but still very usable vertical turning center became easier to operate, and actually realized more cutting time, thanks to a control retrofit that cost only hundreds of dollars.

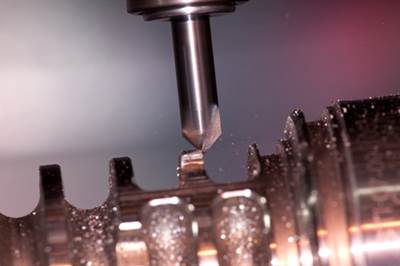

Read MoreTool Certainty

For GKN Aerospace to overcome tool-related variations on its largest milling machines, it had to confront error sources that go unnoticed in many shops.

Read MoreController For Virtually All CNCs

Calmotion says its Lancnc controller provides fast drag-and-drop, bi-directional file transfers between virtually any CNC and PC on a network without additional software. Also, the controller uses a 2-GB secure digital (SD) card to store programs at the CNC, allowing access to program information without using network resources.

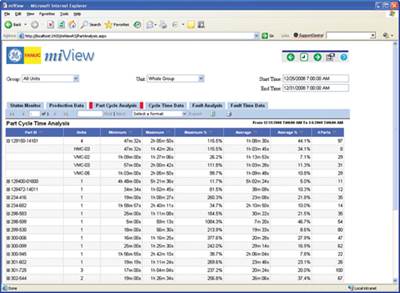

Read MoreAutomating Machine Monitoring And Data Collection

This automated machine data collection software automatically collects a wealth of information specific to machining processes and presents it in an intuitive format so users can quickly analyze the data and implement changes.

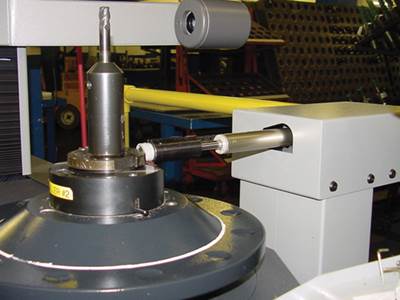

Read MoreProbing for Part Inspection and Crash Avoidance

A reader uses “Ask an Expert” to explore various potential uses of the machining center’s probe.

Read MoreStand-Alone CNC Uses PC Front-End

GE Fanuc Intelligent Platforms, a unit of GE Enterprise Solutions, offers a stand-alone version of its high-performance 0i-D CNC. The stand-alone version, called the 0i-D SA, combines features of the LCD-mounted 0i-D with the flexibility of a Fanuc Panel I PC front-end.

Read MoreMachine Control Aimed At Job Shops And Beyond

The Sinumerik 828D control is said to bring to the "job shop machine tool" a range of features and functionality typically reserved for high-end machine tools.

Read MoreHow to Improve Machining Center Accuracy

Accuracy is not just inherent to the machine—it also depends on how the machine is used. Try these techniques to let a new or existing CNC machining center achieve its potential precision.

Read MoreVideo: Automatic Part Verification Through Reference Comparison

The machining center in this automated production process inspects its own work and updates its own positioning. Probing a known, traceable reference makes this possible.

Watch