Machines

Moving to Horizontal Machining Cuts Shop's Cycle Time by 50%

Adopting horizontal three-axis machining may require much consideration, but Alicat Scientific can attest to almost 50% cycle time reductions with a Kiwa horizontal machine.

Read MoreFlexible Approaches to Gearcutting

Multitasking machine performs multiple gear-cutting processes without the need for a dedicated hobbing machine, providing high-mix gear producers with improved flexibility.

Read MoreMachining 101: What is Five-Axis Machining?

Five-axis machining offers increased productivity and geometric flexibility, but the additional axes of motion can compromise rigidity and accuracy.

Read MoreMachine Tool Data Analysis Identifies Effective Setup Tactics

Thanks to the MTConnect standard, it is easy to create a timeline of a machine’s activities and use it to discover ways for improving operations. One example is how to reduce setup time.

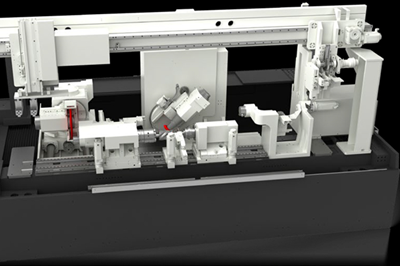

Read MoreJunker Develops All-in-One Grinding Machine

Junker’s Jumat 6L is capable of grinding high efficiency compressor shafts in one setup.

Read MoreNagel Introduces Flexible Bearing Race Superfinisher

The patent pending part drive system can reportedly handle a range of part diameters without any changeover. The new system includes several industry features to make the machine more flexible and productive.

Read MoreMachining 101: What are Machining Centers?

Machining centers offer a wide range of possible operations, but that adaptability comes with the need to stay flexible and perform successful measurements at all times.

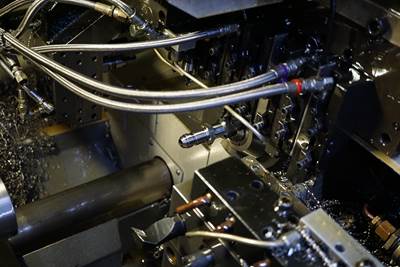

Read MoreTransitioning to CNC Swiss-Type Machining? Here’s How One Shop Did It.

The introduction of CNC Swiss-type machines at Deking Screw Products brought a new and highly efficient production method to the business. But it also required learning the distinct differences inherent with Swiss-type machining, and a mindset change for the company’s leaders.

Read MoreProbing for Setup and Lights-Out Machining — The One-Person Shop Episode #2

Automatic measurement on the machine tool speeds efficiency by day and safeguards capacity at night for a small machine shop.

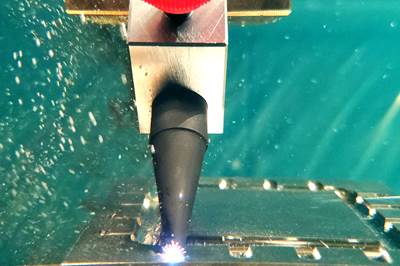

WatchMachining 101: What is Electrical Discharge Machining?

Electrical discharge machining, or EDM, is a non-contact form of machining that projects sparks from an electrode or wire to vaporize material of any hardness.

Read More