Tooling

Kennametal FEG Drill Insert Eliminates End Milling

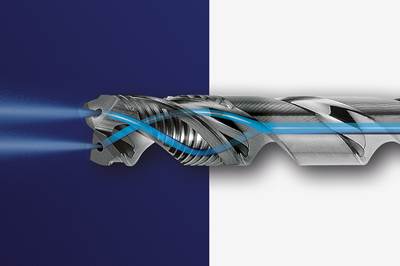

Kennametal’s FEG drill insert is designed to increase the ease of drilling flat-bottom holes into difficult and curved surfaces while eliminating the need for end milling.

Read MoreHow to Choose the Best Drill Type for Your Next Job

Five questions to ask when deciding between solid carbide drills or replaceable insert.

Read MoreCutting Data, Indexable Inserts Optimize Fine Boring

By using digital technology and optimized indexable inserts from Big Kaiser, Schmauser Müller Metalltechnik has increased its process reliability and efficiency in fine boring applications as well as improved tool life.

Read MoreGarant Master Steel Deep Enhances Performance and Longevity

The Hoffmann Group’s Garant Master Steel Deep tool can operate without a co-pilot hole in stainless steel and cast iron.

Read MoreKyocera SGS Expands Micro-Tool Offerings

Kyocera SGS Precision Tools is expanding its micro-tool offerings by more than 4,000 tools, with large increases in its variety of micro-end mills and micro-drills.

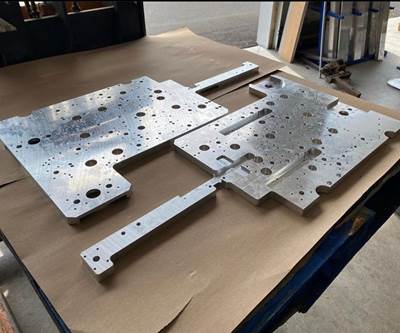

Read MoreMachining a Complex Part in a One-Man Shop

Feature recognition and efficient workholding let this shop cost-effectively produce an intricate part that was bigger than the machine tool's travels.

Read MoreBig Kaiser's Speroni SPI Streamlines Data Transfer

Big Kaiser’s Speroni SPI for tool presetting speeds up tool measurement input while reducing opportunities for user error.

Read MoreRöhm Duro-A Power Chuck Handles Heavier Parts

Röhm’s Duro A power chuck maintains a constant clamping force for more than 500,000 cycles, ensuring reliable component clamping.

Read MoreKennametal Introduces Flat Bottom Geometry for KenTIP FS

The newest addition to Kennametal’s modular drill tip series, the KenTip FS FEG insert is designed to eliminate the need for drilling and end milling flat-bottom holes, instead completing the part in a single operation.

Read MoreJergens Pyramid Risers Provide New Angle for CNC Machining

Jergens’ pyramid risers feature a 30-degree mounting surface to ensure clearance for spindle and cutting tool paths, enabling more machining per setup.

Read More