Workholding

New Direction: An Interview with Kurt Manufacturing

IMTS 2022: Brent Donaldson, executive editor of 91ÊÓƵÍøÕ¾ÎÛ, sits down with Paul Carlsen of Kurt Manufacturing, to chat about the company’s redesigned booth and how it’s designed to solve customer problems.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreWorkholding System Reduces Process Variability

IMTS22: Mate Precision Technologies presents workholding system featuring reduced setup times and process variability.

Read MoreWorkholding System Capable of Holding 10 Parts Simultaneously

IMTS22: Sveconek’s systems can hold up to 10 parts as firmly, accurately and repeatably as two parts being held in a conventional vise.

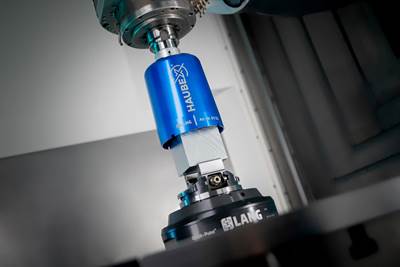

Read MoreHaubex's Automatic Vise Change From Tool Magazine

Lang Technovation’s Haubex is a simple automation solution for small batches that transforms the tool magazine into an automation system.

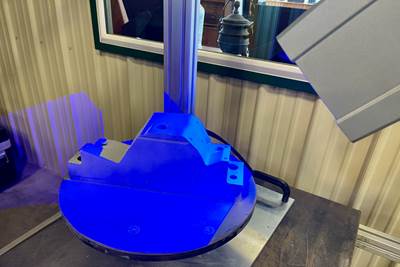

Read MoreMagnetic Workholding Chucks for Increased Holding Force

The workholding chucks are designed to enable more companies to realize the benefits of magnetic workholding by addressing a wider range of applications.

Read MoreWorkholding Solutions for Longer, Unattended Machining

IMTS22: Mitee-Bite Products showcases its range of workholding solutions and design services.

Read MoreWhen To Use A Collet Chuck

Don't assume the standard chuck is the right workholding for every lathe application.

Read MoreBackworking Holders Designed to Reduce Setup Time

IMTS22: iSwiss Corporation will be launching its insert system, the Height Adjustable Backworking Holder X Type, which boasts precise coolant delivery and versatility.

Read MoreSensory Clamping Devices Identify Defects Prior to Machining

IMTS22: Roemheld North America’s new sensory clamping devices enable operators to reject a faulty cast aluminum blank before any machining begins.

Read More