Brent Donaldson Editor-in-Chief

A Dramatic Debut and Key Collaborations at the Paris Air Show

News announcements by aerospace manufacturers and suppliers flew fast and furious throughout the Paris Air Show, but — at least for this writer — the long-awaited debut of the world’s largest engine and a series of announcements by Oerlikon took center stage.

Read MoreMethods Seeks the Perfect Machining Environment

With its new Precision Center, Methods Machine Tools is locking down environmental variables that could impact machining processes. Why? So North American manufacturers will no longer need to send parts, tooling and material to Japan or somewhere else to have intricate, sensitive or challenging test cuts performed.

Read MoreTackling the Aerospace Supplier’s Dilemma: Scalability

Automation and robotics can go a long way toward increasing capacity and growing a business dedicated to aerospace manufacturing. But Trinity Precision has learned that refining the indirect and unseen aspects of its operations can be just as valuable.

Read MoreMission Critical: An Additive Manufacturing Breakthrough in Commercial Aviation

The GE9X is the first commercial aircraft engine to reach production with significant additive content. The story of GE’s accomplishment and why it matters.

Read MoreA Flight Plan for Next-Gen Manufacturing

Learn more about the materials and processes that will shape next-generation aircraft in a collection of stories from 91ÊÓƵÍøÕ¾ÎÛ, Additive Manufacturing and CompositesWorld, available to read or download for free.

Read MoreWhat is the Role of Collaborative Automation in Production?

Thyssenkrupp Bilstein’s North American operations is finding out. The shock absorber manufacturer has eight cobots and counting in its Ohio production facility, plus two autonomous vehicles. Here are scenes from its shop where the picture of automation is changing.

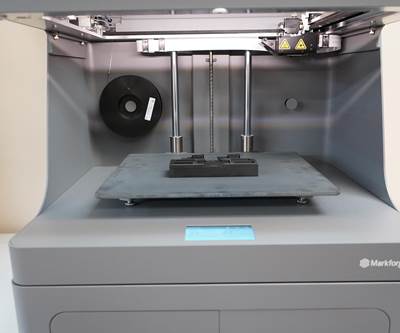

Read MoreThe Case for 3D-Printed Workholding: Collapsing Costs and Lead Times

When Precision Metal Products purchased its first 3D printer last year, the company hoped to collapse both tooling costs and lead times. But the technology’s impact is reaching core business operations, enabling the shop to focus on higher-margin, lower-volume production.

Read MoreVision Systems: One Shop's Competitive Edge for Measurement and Inspection

Even for high-volume machine shops like Alpha Grainger, every part is critical. When the bottleneck to inspect a vast number of parts resulted in lost business, the company built, then invested in, digital vision systems to gain a competitive advantage.

Read MorePreview: One Shop's Evolution from Vertical to Horizontal to Five Axis

Advance CNC Machining’s progression from vertical machining centers through five-axis machining changed more than the complexity of its parts. Ultimately it transformed core business operations.

Read MoreMaximizing Machines, Empowering the Machinist: The Art of Shop Floor Efficiency

When the Great Recession hit Linda Tool, leadership for the 66-year-old machine shop decided against cutting staff. Instead, they made a series of strategic investments and decisions around five-axis machining that has allowed them to scale up the business without increasing headcount.

Read MoreSodick Ushers in an Era of Change Across EDM, Milling and Additive

At IMTS 2018, Sodick is showcasing an era of change with new offerings in its EDM, milling and additive technologies.

Read MoreFlying South: Big Changes and New Innovations for Emag

In addition to an innovative new turning technology, Emag has rolled out numerous changes to its IMTS booth this year—including a move from the north to the south hall.

Read More