Brent Donaldson Editor-in-Chief

Lean Manufacturing Means Taking Nothing for Granted

As foreign competition undercut Valtech Corp.'s business throughout the aughts, the company had a choice to make: Switch production to CNC machining for one of its products, or abandon the product line. Starting from scratch with older machine tools has helped the company scrutinize each step of its processes.

Read MoreAutonomous Bin Picking for CNC Machining Applications

With the launch of a new application kit for collaborative robots, Universal Robots is creating a new option for lights-out machining. But the company may have tapped into a solution for a deeper problem: attracting millennials to the manufacturing workforce.

Read MoreAt Purdue University, Emergency Production of PPE and Ventilator Fittings

After campus had largely shut down, several labs and departments at the venerated engineering school organized with local hospitals to manufacture critical parts needed to fight the coronavirus.

Read MoreDoes Asia's Low-Cost Manufacturing Option Still Make Sense?

As U.S.-based companies try to stay ahead of COVID-19, global supply chains are under renewed scrutiny. Are uncertainties and delays caused by global crises worth the short-term cost savings?

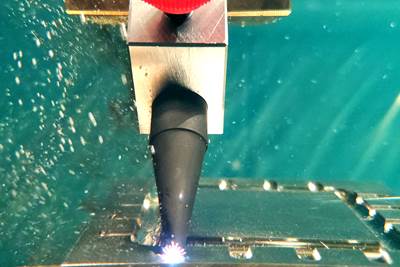

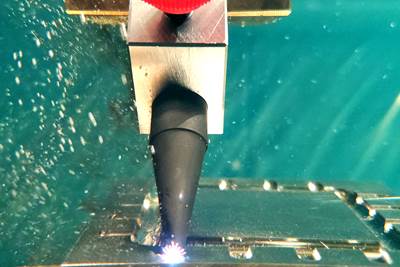

Read MoreCool Tricks: How to Photograph Sinker EDM

Sometimes it takes a little extra effort and ingenuity to solve a problem. In the case of the February 2020 cover of 91ÊÓƵÍøÕ¾ÎÛ, it took a lot of each — and a cheap plastic spaghetti container.

Read MoreInside the Sinker EDM Process, One Spark at a Time

Successful sinker EDM operations rely on understanding the relationship between each individual spark, the electrode and the workpiece.

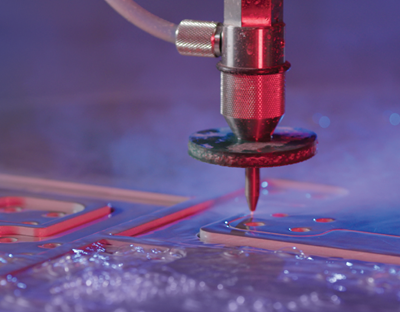

Read MoreWeep Not, Waterjet Machine. Predictive Maintenance is Here.

The versatility of waterjet cutting is well known, but its reputation as a maintenance intensive technology holds it back. Predictive maintenance may change that.

Read MoreWorkflow as a Competitive Advantage

As the cost of machine tools drops and the Baby Boomer generation enters retirement, the nature of competition between machine shops is trending toward data democratization and shop management software.

Read MoreYour Competitors Can Do What You Do

With the barrier to entry for machine shops so low, competitive advantage is not necessarily tied to the ability to machine parts. Increasingly, it is a shop’s ability to document and streamline digital processes that sets it apart from competition.

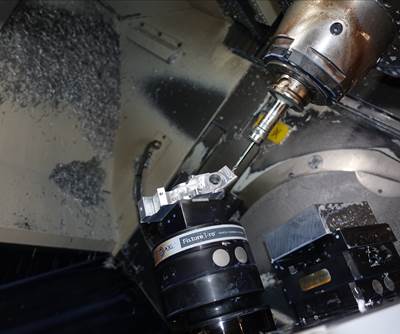

Read MoreHitting the Zone with Five-Axis Machining

By investing in five-axis machining technology, Advance CNC Machining has done more than just add new capabilities to its roster. It has found a way to achieve something that most of us strive for: a way to work “in the zone.”

Read MoreIncreasing Employee Output Through Automation: Here is What We Found in 7 Recent Shop Visits

91ÊÓƵÍøÕ¾ÎÛ editors routinely visit machining facilities to report on shops that are succeeding. Here is what our editors found on seven recent shop visits, all related to using labor more efficiently.

Read MoreMeet Colossus: An Inside Look at One of the Largest Five-Axis Machining Centers in the U.S.

My behind-the-scenes tour on the shop floor of Baker Industries began and ended with its Emco Mecof PowerMill, one of the biggest five-axis machining centers in the United States. The tour also shed light on the company’s highly aggressive approach to new equipment purchases.

Watch