Brent Donaldson Editor-in-Chief

The Culture Change of Large-Part Machining Automation

For Major Tool & Machine in its 75th anniversary year, confronting the skills gap involves a systemized approach focused on automation, and developing and retaining talent.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreThe Art of Maintaining Continuous Improvement

Production efficiencies, setup efficiencies, plant utilization record, safety records, on-time delivery performance — all of these metrics and more place Forest City Gear among the elite when it comes the use of ongoing improvement methodologies.

Read MorePMTS Day Two Brings Tech Talks, Demos and Crowds

The 2021 Precision Machining Technology Show is the manufacturing industry’s first event in over 18 months — and has brought the crowds to match! Today, attendees will see demos, hear presentations and visit 250+ exhibitors.

Read MoreNo Such Thing as Luck: A One-Person Shop Owner’s Success Story

You could say he’s a lucky Guy. He has the ideal setup for a moonlighting at-home-machinist: The perfect location, the perfect day job, and a double-threat skill set that allows him to hire himself for prototyping and low-volume production work. But Guy Driscoll’s biggest talent might be creating his own luck.

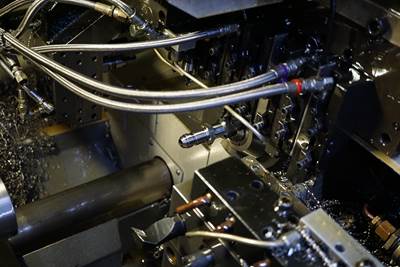

Read MoreTransitioning to CNC Swiss-Type Machining? Here’s How One Shop Did It.

The introduction of CNC Swiss-type machines at Deking Screw Products brought a new and highly efficient production method to the business. But it also required learning the distinct differences inherent with Swiss-type machining, and a mindset change for the company’s leaders.

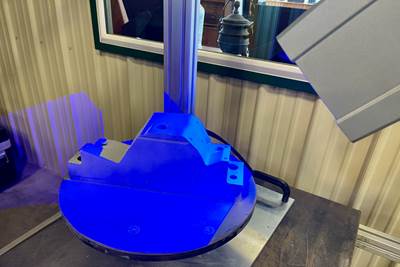

Read MoreMeet the Automation That Makes Machine Tool Automation

A new manufacturing cell at Mazak’s North American headquarters is one part machine tool production unit and one part demonstration facility. And it’s here to provide a lesson about how automation can tackle skilled-worker shortages and supply chain issues at the same time.

Read More91ÊÓƵÍøÕ¾ÎÛ– Season 1 Episode 6: The Way Forward

So far, 91ÊÓƵÍøÕ¾ÎÛhas looked into system-wide effects of broken supply chains, automation, skilled workforce issues and our perception of manufacturing jobs — examining each topic through a prism of individual experiences. For this final episode for Season 1, let’s look at one more system-wide question and bring it back to personal perspectives: Is there today a new dawn, a new moment for American manufacturing?

Listen91ÊÓƵÍøÕ¾ÎÛ- Season 1 Episode 5: Succession - A Family Machine Shop Story

The story of Geno and David DeVandry reflects the sea change in machine shop ownership facing this country as baby boomers reach retirement age. The change in leadership from father to son at their family-owned machine ship required a new mindset, a new way running the family-owned business, and that one generation let go and allow a new one to step in.

Listen91ÊÓƵÍøÕ¾ÎÛ- Season 1 Episode 4: Making the Case for Manufacturing

The majority of Americans want to "bring manufacturing back" to the U.S. The problem? Many of these same people do not want their children to work in manufacturing because of outdated beliefs about what a machine shop looks like.

Listen91ÊÓƵÍøÕ¾ÎÛ- Season 1 Episode 3: The Supply Chain Knot

Through interviews with manufacturing leaders and economists, Episode 3 of “Made in the USA” explores the benefits and challenges of keeping manufacturing production within the United States — especially after major events such as 9-11 or the onset of a global pandemic.

Listen91ÊÓƵÍøÕ¾ÎÛ- Season 1 Episode 2: The Automation Puzzle

There is a fundamental question we need to answer when we talk about automation: To what extent is automation an answer to the skilled workforce shortage, and to what extent is automation vs. Skilled labor the wrong comparison to make in the first place?

Listen