Brent Donaldson Editor-in-Chief

New Direction: An Interview with Kurt Manufacturing

IMTS 2022: Brent Donaldson, executive editor of 91ÊÓƵÍøÕ¾ÎÛ, sits down with Paul Carlsen of Kurt Manufacturing, to chat about the company’s redesigned booth and how it’s designed to solve customer problems.

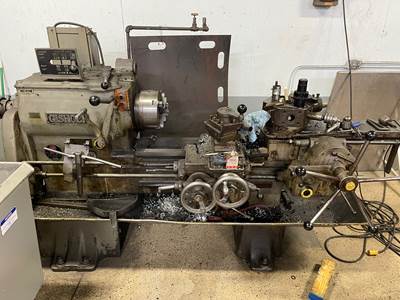

Read MoreWeiler to Debut New Automation Features For Its Lathes

Weiler’s V 110 four-way precision lathe introduces features new to the U.S.

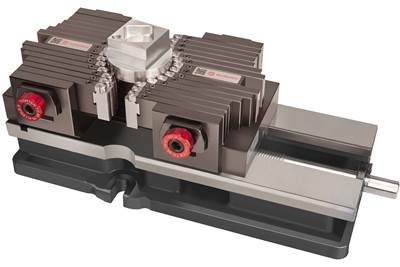

Read MoreNew Division, New Product: An Interview with Norgren Workholding

Brent Donaldson of 91ÊÓƵÍøÕ¾ÎÛ chats with Corey Shidler of Norgren Workholding on the company's new soft jaw.

Read MoreNiche Work If You Can Get It: A CNC Machine Shop Crafts Its Own Destiny

The latest innovations in metalworking aren’t always related to CNC automation or robotics. For Rosenberger North America, a 2022 Top Shops Honoree, it is the company’s niche processes that create the biggest successes.

Read MoreWhat to Do When Five-Axis Machining Is Off the Table

For Fischer USA, 3+2 machining with a high-precision rotary table adds flexibility without the cost of a full five-axis machine.

Read MoreBeyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

Read MoreInside an Amish-Owned Family Machine Shop

91ÊÓƵÍøÕ¾ÎÛ took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Read MoreHeavy Engineering: The Complex Logistics of Moving Large Machine Tools

One of our fascinations with large-format machine tools has little to do with their capabilities, but everything to do with the logistics involved with getting them up and running. Here’s how one of the world’s oldest builders of giant machine tools tackles the challenge.

Read MoreFearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read MoreA New Player in the Swiss-Style Machine Market

Mazak has officially entered the Swiss-style market with its new line of Syncrex machines. Here’s what two of the company’s leaders had to say about the decision.

Read MoreWhen Too Many Customers Spoil the Part

Duo CNC used to take on as many customers as the shop could handle. But when growth stalled, a top-down audit by the company’s general manager revealed that its customer base was inhibiting growth — and causing the shop to be less efficient and productive.

Read MoreIs That a CNC? Major Tool Edition

The cover of 91ÊÓƵÍøÕ¾ÎÛ’s November issue features a striking image: Three employees checking bore and thread sizes on a massive machined aluminum part — which is situated inside an even more massive five-axis machine tool. The caption reads, “Automation Still Needs You.” Curious about what you are seeing? Read on.

Read More