George Schuetz Director of Precision Gages

More Surface Finish Parameters at Hand

Measuring surface finish at the point of manufacture is often done by the same machinist who is manufacturing the part. They need tools that meet test requirements and are easy to use.

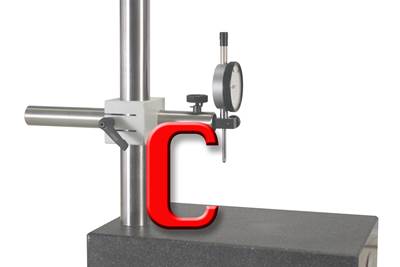

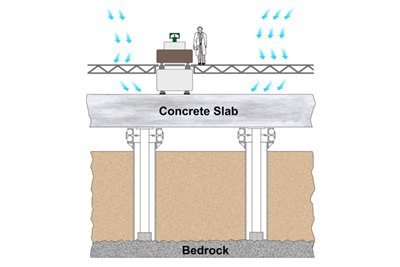

Read MoreThe Nuts and Bolts for Getting the Gaging Fixtures Right

Gage fixtures are the key to accurate and repeatable measurements, so make sure there is no play at its joints.

Read MoreDigital Comparators are More Than Just Readout Devices

Modern digital comparators often combine the performance of touchscreen phones, LVDTs, digital amplifiers and even small PCs into the size of a standard dial indicator.

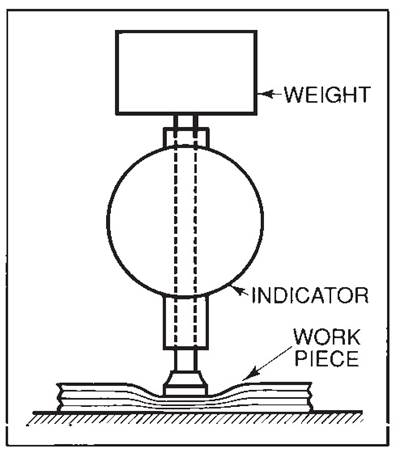

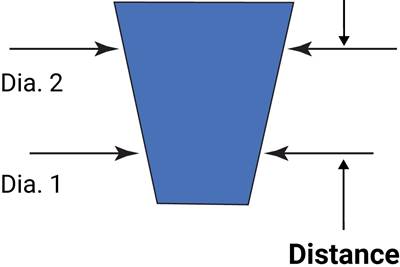

Read MoreThe Many Ways of Measuring Thickness

While it may seem to be a straightforward check, there are many approaches to measuring thickness that are determined by the requirements of the part.

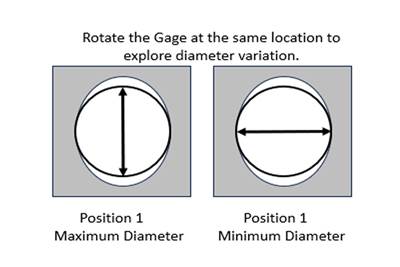

Read MoreTips for Anticipating Hole Conditions

When measuring an ID with an indicating plug gage, it is OK to slow down to learn more about the hole being measured and explore for extraneous conditions.

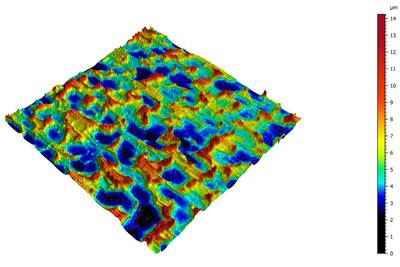

Read MoreMoving from Contact to Noncontact Surface Analysis

2D measurement systems check specific lines for roughness quality, while a 3D surface analysis provides assurance for a broader area — which can avoid costly process disruptions and bonding failure.

Read MoreHow to Choose the Correct Fixed-Body Plug Gaging Solution

The two types of fixed-body plug gages are both accurate, fast and easy to use. Consider these factors when selecting one for your gaging application.

Read MoreCombining Multiple Probes: A Recipe for Success

Combining measurement techniques enables a wide range of relational characteristics to be measured with just one or two sensors.

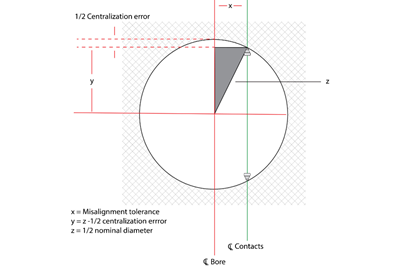

Read MoreCentralization Errors Grow as Bores Get Smaller

It is important to consider the effects of gage centralization when measuring smaller bores. Selecting the right tool is often based on the bore’s size and tolerance.

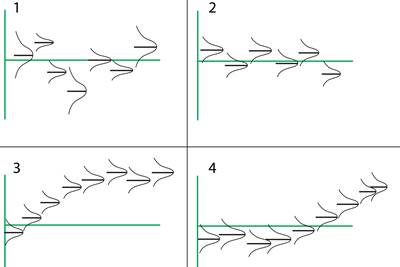

Read MoreWhen Evaluating Gage Stability, a Picture Says 1,000 Words

Gage capability programs can help analyze the cause of stability problems, but it can be revealing to manually sketch out histogram data to get a pictorial view of what is happening.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreChoosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Read More