George Schuetz Director of Precision Gages

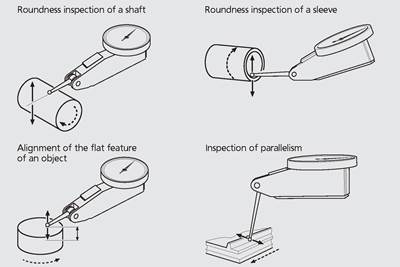

How to Choose the Right Dial Indicator

Digital alternatives are replacing dial indicators – but dial indicators can still be useful. Here’s how to select the right one for a given application.

Read MoreHow to Correctly Measure Surface Finish

When providing surface finish specs, engineers sometimes leave out the actual testing parameters. Here’s how to be sure measurements are as accurate as possible.

Read MoreThe Right Gage for Measuring Small Bores

Small bore holes present a unique set of challenges for precision measurement, but small mechanical bore gages can be used for tight tolerances in this application.

Read MoreTest Indicators Excel for Tight Tolerances and Small Spaces

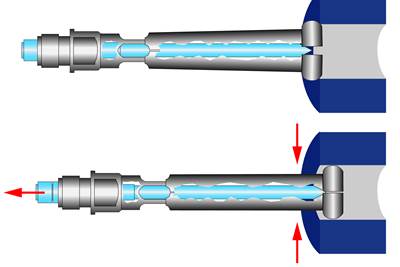

Test indicators are sometimes overlooked or replaced by dial or digital indicators, but for some situations, they can’t be beat.

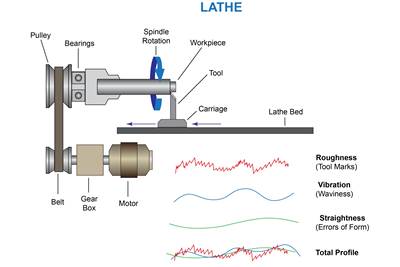

Read MoreVibration: An Invisible Source of Gaging Error

Vibration can make or break a gage’s performance, but vibration errors can be resolved by using a vibration isolation table or other correction measures.

Read MoreModern Bench Amplifiers Offer More Evaluation Capabilities

Today’s electronic gaging amplifiers can do more than take comparative measurements. New features have become common, opening possibilities for machinists and manufacturers.

Read MoreHow to Make a Surface Plate Into a Gage

Surface plates provide a stable reference surface on a large scale, enabling multiple gage setups, but they can also be turned into a gage themselves.

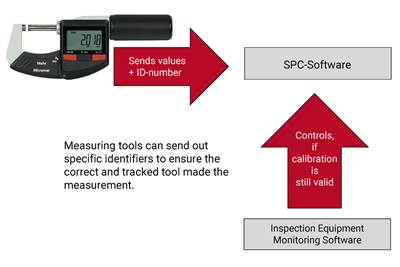

Read MorePreparing SQC For Machinists and Future Requirements

The current complexity of machines means machinists are already busy — assigning them new, expanded SQL duties (such as gage identification) will require gages and processes to prioritize accessibility.

Read MoreHow to Successfully Transition from Dial Indicators to Digital

Digital indicators bring a wealth of benefits over dial indicators, but simply swapping one for the other can lead to problems in repeatability and process durability.

Read MoreProperly Reading Dial Indicators

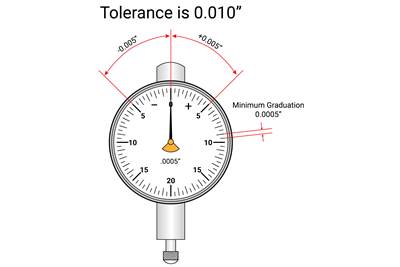

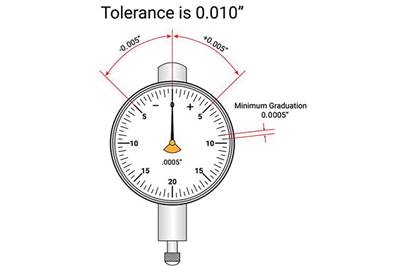

Dial indicators provide useful readings about tolerance ranges at a glance — but new users need to know how to set up these indicators before using them.

Read MoreWhat to Know About Decoding Surface Finish Gages and Parameters

Long-wavelength waviness and short-wavelength roughness require a wide variety of instruments and parameters for proper measurement — and lower numbers aren’t always better.

Read MoreHow to Match Thickness Gage Types to Proper Applications

Different thicknesses require different gage types during inspection — four common ones are handheld indicators, handheld micrometers, opposed air streams and gage blocks.

Read More