George Schuetz Director of Precision Gages

Calling Home on a Portable Surface Gage

Today’s surface gages have a user interface that is just like a smartphone, and setting them up to make measurement requirements should be easy for the operator.

Read MoreHow to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

Read MoreBring the Surface Finish Check to the Part

Dedicated handheld gages can assist the operator in making critical checks.

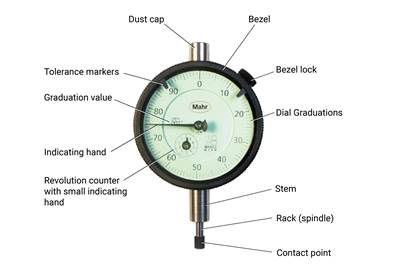

Read MoreReading What the Dial Indicator Is Saying

Dial indicators provide good value for their resolution. With a glance, one can quickly determine if the part is larger or smaller than the master setting and by a degree of how much.

Read MorePerformance Digital Comparators Offer an Alternative to Bench Amplifiers

Electronics today allow for matching the linear variable differential transformer performance and digital indicator size into a new digital comparator that provides even more value than traditional bench amplifiers.

Read MoreDetermining Out-of-Roundness at the Point of Manufacture

George Schuetz, Mahr Inc.’s Director of Precision Gages, offers these techniques for measuring roundness on the shop floor.

Read MoreSensitive and Strong: Advanced Digital Comparators

Borrowing from cell phone touchscreen technology, user interfaces on industrial gages are increasingly sensitive — and strong.

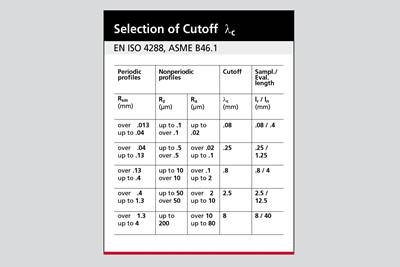

Read MoreHow to Choose the Right Cut Off When Measuring Roughness

Measurement results for surface finishing parameters can vary depending on the filter parameter (Lc), also known as the cutoff.

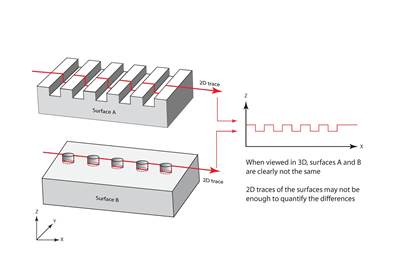

Read MoreWhen Manufacturers Should Use 3D Measurement for Surface Finishing

Two-dimensional (2D) surface profiling systems are the standard for quality assurance in manufacturing, but some applications demand 3D measurement systems.

Read MoreWhat Manufacturers Need to Know About Metrology

As manufacturing technology advances, measurement processes evolve to stay one step ahead.

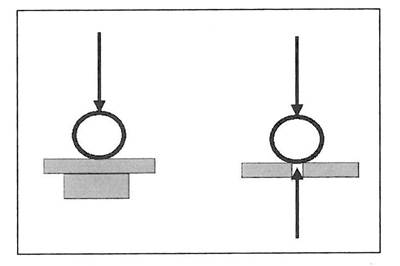

Read MoreDifferential Gaging: 2 Big Benefits for In-Process Part Control

Differential gaging offers benefits like reducing operator influence and enabling quick in-process checks.

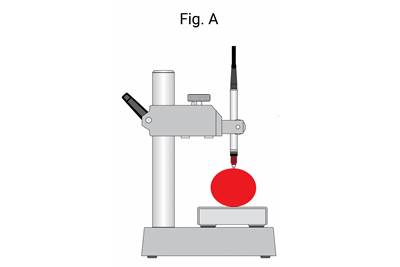

Read MoreHow to Improve Comparator Stand Performance for Gaging

Adding digital display systems and high-precision probes to comparator stands brings new functionality and pitfalls. The right setup can minimize errors.

Read More