Columns

Breaking SPC Limitations Without Breaking Rules

Machine learning helps prove the merit of statistical analysis techniques that do not require plotting CNC machining quality data on a bell curve.

Read More7 CNC Parameters You Should Know

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized.

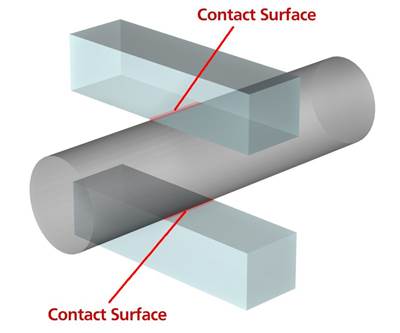

Read MoreThe Versatility of Snap Gages

The many design modifications available in snap gages enables them to measure some of the most difficult dimensions, right at the point of manufacture.

Read MoreERP Helps Forward-Thinking Manufacturers Look Back

Enterprise-wide performance data and an understanding of which metrics matter form a foundation for the predictive analytics that characterize “smart” CNC machine shops.

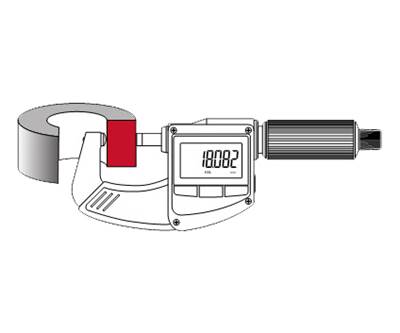

Read MoreHow to choose a micrometer that fits your needs

Match your micrometer choice to your specific machine shop needs.

Read More5 Things New CNC Machine Operators Must Know

These subjects are the building blocks of training newcomers on a specific CNC machine tool.

Read MoreCenter of Excellence Is New Twist on Old Manufacturing Department Structure

The new Spirit AeroSystems facility for five-axis machining allows a small team to oversee a significant amount of machining capability. Is this the way of the future as machining systems become more automated?

Read MoreMonitoring Time for Preventive Maintenance Tasks

Not all maintenance tasks should be performed based on a calendar date. You can use a custom macro to monitor your machines.

Read More3 Mindset Changes for Lights-Out CNC Machining

Expanding capacity into the unattended hours calls for counterintuitive new ways of thinking about the work.

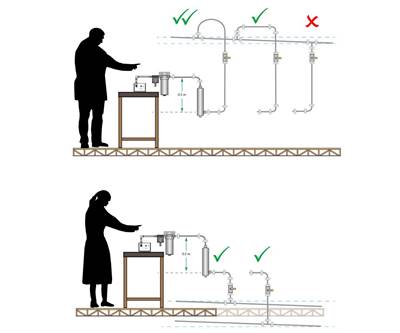

Read MoreMaintaining an Air Gage System’s High Performance

Tight, clean and dry: The requirements of air gaging aren’t very different from mechanical gaging.

Read MoreData-Driven Manufacturing Scales Down

An automatic gaging station demonstrates the potential of shopfloor connectivity at the level of the individual machine tool.

Read More