Columns

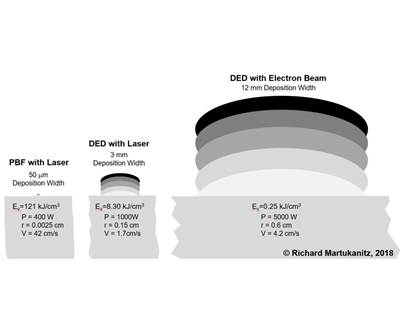

Additive Manufacturing for Large Parts

Powder-bed fusion is driving the hype for additive manufacturing right now, but it may not be the best answer. Directed energy deposition is a strong contender.

Read MoreUnderstanding CNC Machine Accuracy and Repeatability

Properly evaluating machine tool capability requires understanding how the both user and the builder can influence precision.

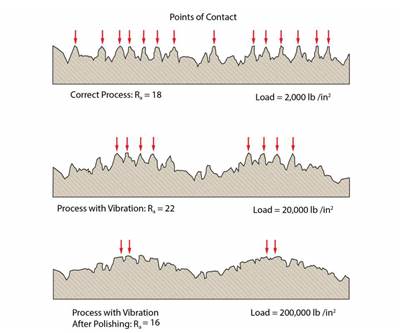

Read MoreWhat Do Manufacturers Really Know About the Surfaces of the Parts They Are Producing?

Knowing only the average roughness may not be enough. Other surface parameters can affect product quality.

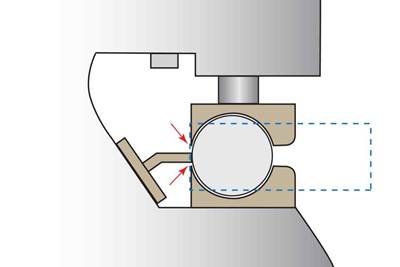

Read MoreJust This Once, You Can Blame the Gage

Even the old, reliable gage is subject to wear. George Schuetz, director of precision gages at Mahr inc., gives guidance for machinists to maintain their gages.

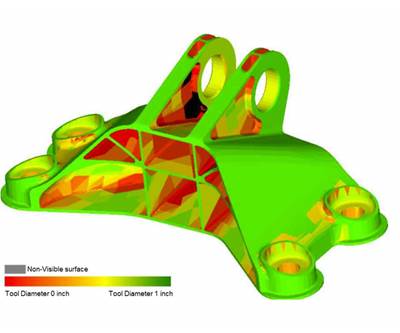

Read MoreCan My Machine Tool Access My Support Structures?

Analyzing the machinability of support structures opens a new way of thinking about optimal build orientation.

Read MoreKeeping Your Company in the Loop

Demand that all employees are constantly learning and staying up to date with the latest manufacturing technology.

Read MoreWhy Is My Surface So Rough?

Be aware of the inherent manufacturing and design challenges that impact the dimensions and tolerances that you can (or cannot) achieve on an “as built” part.

Read MoreDocumenting Your Data Collection

Industry 4.0 helps tie gaging equipment data with part measurement for 100 percent traceability.

Read More10 Ways to Think Differently about Robotic Automation

Take another look: A lot is happening in and around robotic automation. What robots might mean for machining and manufacturing is getting ready to change.

Read MoreLess Is More with Dial Comparators

Why use a dial indicator with more than the needed range? A dial comparator offers less risk of misreading the dial without the cost of an electronic gage.

Read MoreThe Urgency of Producing a Start-Part

Production cannot begin until the first workpiece is produced and passes inspection.

Read More