Columns

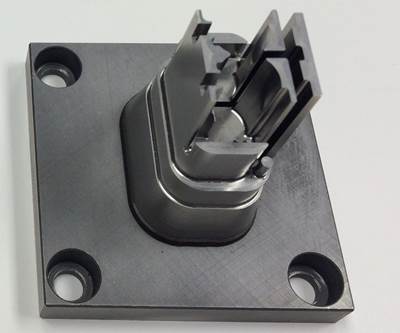

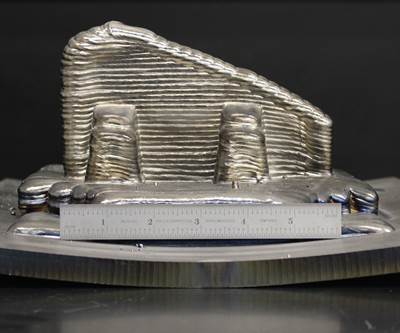

Additive Manufacturing for Hard Tooling

Hybrid manufacturing is enabling tooling to be made with additive processes.

Read MoreManufacturing to Meet Tech Community at MT360

I will hold onstage conversations with additive manufacturing and collaborative automation leaders as part of the new technology event to premier May 12-14, 2020, in Santa Clara, California.

Read MoreConverting Time and Date to a More Useful Format

FANUC and FANUC-compatible CNCs have multiple ways to monitor time. They are accessed by four system variables: milliseconds clock, hours clock, current date and current time. Here’s how to format information in a helpful way.

Read MoreAI Makes Shop Networks Count

AI assistance in drawing insights from data could help CNC machine shops and additive manufacturing operations move beyond machine monitoring.

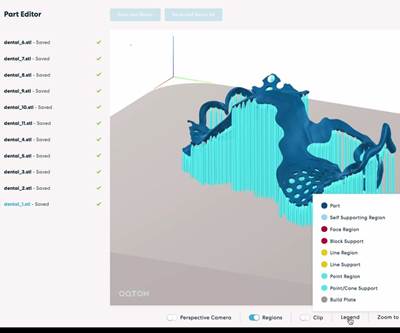

Read MoreCombining Additive and Subtractive Processes for Hybrid Machining

At this point, we are still learning how to combine the two to optimize hybrid manufacturing.

Read MoreUsing Offset Data to Determine Turret Index Position

Determine the optimal index position based on cutting tools’ current geometry offset settings.

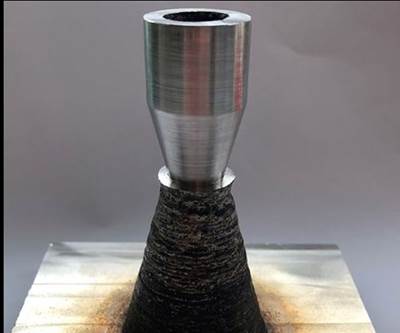

Read MoreAdditive Manufacturing with Wire

This system has the benefits of cheaper cost and easier handling. But there can be some drawbacks as well.

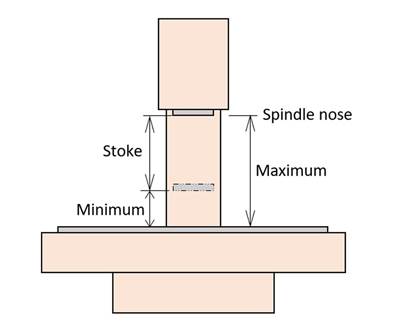

Read MoreMeasuring Tools Basics: Faster and Better

In a high-volume production environment, the cost of inspection is related to the speed with which measurements can be made and interpreted.

Read MoreThe Case for Consistency

Why do manufacturers ask their employees to work within defined systems? Here's why consistency matters.

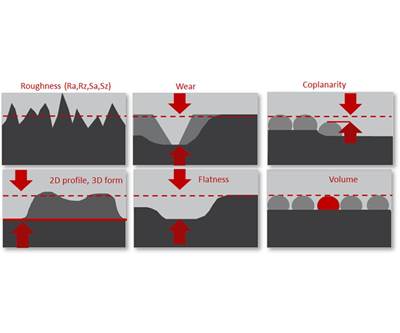

Read MoreMeasurement for True Surface Analysis

Optical metrology is providing more information, faster, about surfaces that were once impossible to measure and understand.

Read MoreCollaborative Robots Learn to Collaborate

Accessible 3D vision unlocks the potential of machine learning for making our autonomous partners more humanlike.

Read MoreChecking Cutting Tool Offset Values

A setup program can be used to test for overtravel issues before a workpiece is run, eliminating program verification delays.

Read More