SCHUNK, Inc.

211 Kitty Hawk Drive

Morrisville, NC 27560 US

800-772-4865 | 919-572-2705

info@us.schunk.com

CONNECT

IS THIS YOUR COMPANY?

Video Gallery

Hannover Messe 2025: SCHUNK präsentiert die Zukunft der Automation

Tauchen Sie ein in die Welt der Innovation und Technologie auf der Hannover Messe 2025! In diesem Video zeigen wir Ihnen die ...

KONTEC Konfigurator von SCHUNK: Komplette Spannlösungen selbst konfigurieren

Komplette Spannlösungen nach Wunsch selbst kombinieren – mit dem KONTEC Konfigurator von SCHUNK. Ihre Vorteile: ...

Applikationsworkshop 2025: Einblicke und Impressionen

Die praxisnahe Einführung in die Grundlagen der Automatisierung Als erfahrener Experte für Automatisierung und ...

System Daix Open House 2024: Technology and Collaboration

Steigere deine Produktivität: Erfahre, wie innovative Technologien und Zusammenarbeit deine Effizienz im Fertigungsprozess ...

As Seen On 91ÊÓƵÍøÕ¾ÎÛ

SCHUNK, Inc. Supplies the Following Products

- Actuators, Hydraulic & Pneumatic

- All Other Workpiece Handling, Loading & Feeding Equipment not specified

- Arbors (for Cutters)

- Arbors, Expandable Workholding

- Chuck Jaws & Collets

- Chucks, Collet Type (for Workholding)

- Chucks, Gear

- Chucks, Jaw Type

- Chucks, Magnetic

- Chucks, Power

- Chucks, Precision

- Chucks, Self-Contained

- Chucks, Special

- Clamps & Fixturing Devices

- Collets, Solid & Master

- Conveyors & Other Part Handling Automation

- Drill Chucks

- Fixturing Systems

- Hydraulic & Pneumatic Equipment

- Lifting & Positioning Equipment

- Linear Guides

- Magnets & Magnetic Devices of all Kinds

- Manual Lathes

- Nano & Micro Machining

- Pallet Changers - Automatic

- Pallet Changers - Manual

- Pallet Systems

- Pedestal Type Fixtures & Tombstone Blocks

- Press Automation Devices

- Press Feeds & Loading Equipment

- Robot Tooling/Grippers

- Servo Motors, Linear

- Servo Motors, Rotary

- Slides

- Steady Rests

- Tool Presetters

- Tool Presetting Equipment

- Toolchangers

- Toolholders

- Tooling Systems, Modular and/or Quick-Change

- Vises & Vise Jaws

- Workholding, Custom

Trade Names Offered by SCHUNK, Inc.

- KONTEC

- PGNplus

- TANDEM

- SINO

- TRIBOS

- PRISMO

- CELSIO

- SRU-plus

- FORTIS

- ACURO

- PZNplus

- SCHUNK VERO-S

- MAGNOS

- ROTA

- SCHUNK

- TENDO

Editorial, News, and Products

-

Five-Axis Machines Speed NASCAR Engine Production

Moving from an aging set of five-axis mills to more advanced machines enabled Hendrick Motorsports to dramatically improve its engine production.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

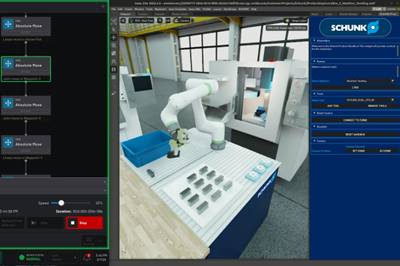

Schunk Partners With Ready Robotics to Develop Simulation Tool

Automation Explorer will enable users to interact with Schunk automation technology in an immersive and detailed, physics-based simulation tool.

-

Grob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

-

Automation and Flexibility Counter Inflation at BI-MU 2022

Automation headlined BI-MU 2022, while flexibility underscored exhibitors’ products. These twin benefits may be shops’ greatest assets against inflation.

-

Partial Automation Inspires Full Cobot Overhaul

Targeting two-to-four hours of nightly automation enables high-mix manufacturer Wagner Machine to radically boost its productivity past a single shift.

-

Simple Workholding for Robotic Automation

Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

-

Schunk Acquires German Hydrostatic Systems Specialist

Hyprostatik Schönfeld’s product range includes lead screws with hydrostatic nuts, guide shoes, tailstocks, spindle bearings and rotary tables in different sizes and designs.

-

Schunk Makes a Gripping Debut at IMTS

By taking inspiration from gecko feet, Schunk has developed a residue- and particle-free adhesive robotic gripper that holds up to 35 pounds.

-

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

-

Schunk Upgrades Low Maintenance, Quick-Change Jaw Chuck

Schunk says its Rota THW3 quick-change jaw chuck is particularly beneficial for users who produce small and medium quantities and are frequently switching between jobs.

-

Schunk's New Chuck Jaw Clamps a Range of Geometries

Schunk’s Rota-M Flex 2+2 chuck jaw is designed to provide increased flexibility for clampable workpiece geometries and a variety of possible applications.

-

Gripper Finger Change System From Schunk Reduces Setup Time

Schunk claims its toolless jaw quick-change system reduces setup times to a minimum, therefore increasing the productivity and flexibility of the entire system.

-

Schunk's Hydraulic Toolholder Features Imbalance Correction

Constructed of durable hardened tool steel, the Tendo Platinum V2 reportedly improves stability, stiffness and clamping force to support sustained accuracy throughout its life.

-

Norgren Introduces One-Size-Fits-All Soft Jaw

Norgren’s Adaptix Soft Jaw uses adjustable fingers and interchangeable tips to grip a wide variety of parts or workpieces during the CNC machining process.

-

Schunk Updates Chuck Technology

Schunk says the technologies included in the THW3 chuck result in high process reliability, quick jaw changes, constant clamping forces and long maintenance intervals.

-

Schunk Announces Magnetic Gripper

Schunk’s EMH electro-permanent magnetic gripper has a compact, energy-efficient design.

-

Moving Monitoring Closer to the Cut

A sensory toolholder can provide more accurate vibration data on the metalcutting process, helping to extend tool life and improve surface finish.

-

Schunk Rota-M Flex 2+2 Maximizes Mill-Turn Flexibility

Schunk’s Rota-M flex 2+2 chuck jaw offers a level of flexibility that the company says is unmatched on the market and covers a wide range of part geometries.

-

Schunk Clamping Force Block Provides Automation Entry Point

Schunk’s Tandem PSG3-LH 100 clamping force block provides a low-maintenance solution for transitioning into automation for basic aluminum and plastics machining applications.

-

Schunk's Vero-S NSE Mikro 49-13 Clamps Small Parts

Schunk’s Vero-S NSE Mikro 49-13 is a completely sealed miniature clamping module specifically for metalcutting, assembly, handling and measurement applications.

-

Schunk's Tendo Slim 4ax Now Available with Coolant-Through

Schunk now offers a version of its Tendo Slim 4ax with Cool-Flow coolant-through technology.

-

Schunk's Rota NCR-A Maintains Grip by Preventing Grease Contamination

The Rota NCR-A, a sealed six-jaw pendulum compensation chuck from Schunk, is designed with seals at the jaw interface and the piston to keep the grease from being washed out.

-

A Shop Where a Machine Loads Itself

Instead of investing in an external robotic loading system, this shop adopted technology that lets a machine tool load parts on its own.

-

Schunk Kontec KSC Vise Optimized for Use with Palletized Automation

The Schunk Kontec KSC clamping vises are made for raw and finished part machining.

-

Pneumatic Gripper Provides Greater Grip Force

Schunk’s PGN-Plus-P gripper features enlarged supporting dimensions between the six load-bearing shoulders of the multi-tooth guidance, allowing higher moment capacity, in turn accommodating longer fingers and greater loads.

-

Three Expectations for Robotic Automation

Shops take some modern robot capabilities as given, but a recent trade show in Japan demonstrated ways those capabilities continue to improve.

-

Workholding Enables Stress-Relief Reclamping

IMTS 2018: The Schunk Vero-S Aviation product line is designed to rigidly clamp large parts accurately and enable the user to release the part enough to allow the part to move (compensate) due to the stresses of machining without fully releasing the part.

-

Collaborative Robot Gripper Design, Development: Four Trends You Need to Know

Safety standards, third-party certifications, plug-and-play packages and new sensor technology for grippers designed for collaborative robots are making them safer, stronger and easier to use.

-

Clamping Line Accommodates Large Aerospace Parts

The Schunk Vero-S Aviation product line clamps large parts accurately, enables the parts to be moved, and establishes data points through four modules.

-

Jaws Increase Efficiency in Finish Machining

The jaw design of Schunk’s UVB-HS soft chuck jaws provides efficient gripping for lathe workholding.

-

Modular Clamping System Accommodates Freely Molded Parts

The Schunk Vero-S WDB modular clamping system provides the efficiency levels of the Vero-S quick-change pallet system to machine directly clamped workpieces.

-

Lightweight Chuck Enables Machining of Heavy Workpieces

The Rota-S Flex from Schunk is a flexible manual chuck for machining a variety of workpieces on milling and turning machines.

-

An Automation System for a Job Shop Environment

A flexible robotic part-loading and unloading system enables a small Indiana shop to boost production without a large investment.

-

Toolholder Damps Vibration, Reducing Wear

The Tendo Platinum toolholder from Schunk is designed for durability, ease of use and precision for many milling, drilling and reaming applications.

-

Manufacturing News of Note: September 2017

Schunk to add square footage and jobs to its U.S. headquarters, a pre-apprenticeship program for women commences 11 graduates, and other industry news.

-

Schunk USA Breaks Ground on Headquarters Expansion

The two phases of the project will add some 19,000 square feet of manufacturing space and 22,000 square feet of tech center, training and office space by the end of 2018, expanding what is already the company’s largest facility outside of Germany.

-

Quick-Change Pallet System Works with Various Table Sizes

Schunk’s Vero-S NSL quick-change workholding and positioning system is designed to speed setups with the ability to mount any workholding on top, from a standard vise to a custom fixture, for reliable and consistent change-over.

-

Schunk Opens Service, Technology Center in Houston, Texas

The center offers a range of services to local manufacturers.

-

One Next-Step Advancement for Cobots: Specialized Grippers

Grippers and end-effectors developed specifically for collaborative robots represent new advancements in this type of robot technology.

-

Hydraulic Expansion Toolholder Transfers 520 Nm of Torque

Schunk’s Tendo E Compact toolholder eliminates the need for different holder technologies for milling, drilling and reaming.

-

Hydraulic Toolholder Maintains Runout Accuracy

Schunk is expanding its line of hydraulic expansion toolholders with the Tendo Aviation designed for demanding applications such as those commonly performed in the aerospace industry.

-

Optimum Workholding Increases Output

This investment casting company doubled production of a series of parts by incorporating workholding into a cell that keeps pallets constantly moving across the machine tool.

-

Video: Machine Tool Serves as its Own Robot

Schunk’s Gripper with Spindle Interface device enables a machine to load and unload workpieces on its own. See how.

-

Manually Actuated Clamping Devices Ease Tool Changes

The SVP-Mini and SVP-RM manually actuated clamping devices from Schunk are run on factory-defined set pressure.

-

Custom Clamping Concept Optimizes Multitasking

To get the most potential out of its multitasking machine, Trumpf uses a detailed custom clamping concept from Schunk.

-

Weldon-Flat Tools in a Precision Toolholder

This system uses the standard Weldon flat so that end mills do not have to be modified for locking in place when a precision toolholder takes high-force cuts.

-

Quick-Change Pallet System Module Holds Small Workpieces

Designed for use with Schunk's Vero-S quick-change pallet system, the Vero-S SPM plus 138 diaphragm clamping module is machinable to accommodate the contour of a specific workpiece.

-

Toolholder Extension Expands Machining Access

Schunk’s Tribos-SVL toolholder extension enables precise, smooth machining of workpiece areas that are difficult to access.

-

Quick-Change Pallet System Provides Universal Standard

The NSL series of Schunk’s Vero-S system enables shops to quickly and easily implement a quick-change pallet system with a universal standard.

-

Quick-Change Chuck Eliminates Jaw Re-Boring

Schunk’s Rota THWplus quick- jaw-change chuck is designed for flexibility and efficiency in setups.

-

Vise for Minimum Clamping Surfaces

Schunk’s Kontec KSX NC vise for simultaneous five-axis machining is designed to handle tool-free adjustable clamping forces between 4 and 40 kN measured directly at the workpiece.

-

Quick-Change Pallet Toolbox Components Made of Stainless Steel

The Schunk Vero-S quick-change pallet toolbox features functional components made of hardened stainless steel, including the base body, clamping pin and clamping slide.

-

Upon Further (A3) Review

Using lean manufacturing’s A3 problem-solving process, Genesis Attachments found that magnetic workholding could provide greater benefits than simply getting parts on and off machines faster.

-

Miniature Self-Centering Vise Offers Precision Clamping

Schunk’s Tandem KSP+64 is said to be a major development in miniature, self-centering clamping technology.

-

Universal Hydraulic Toolholder for Small-Quantity Runs

Schunk’s Tendo E compact toolholder is designed for milling, drilling and reaming applications.

-

Toolholder Directly Clamps Small Tools

Schunk’s Tribos-Mini toolholder directly clamps small tools for challenging applications, including machining medical, dental and micro-level parts.

-

Toolholder Clamps Without Additional Components, Change-Overs

Schunk’s Prismo holder for automated tool and cutter grinding is designed to clamp diameters ranging from 5 to 20 mm without additional components or change-overs, and features repeat accuracy of less than 0.005 mm.

-

Cycle Efficiency

Automated machining processes enable this maker of high-performance mountain bike parts to manufacture efficiently with minimal staff.

-

Mini Toolholder Clamps Small Tools

The Tribos-Mini toolholder from Schunk directly clamps small tool shanks along the entire axis virtually eliminating collets, collet nuts and inconsistent cutting tool clamping.

-

Radial Pole Magnets for Hard and Finish Turning

For exact machining of thin-walled rings on rotary tables, cylindrical grinding machines and lathes, Schunk offers standardized magnetic chucks with radial pole pitch.

-

Composites Machining for the F-35

Lockheed Martin’s precision machining of composite skin sections for the F-35 provides part of the reason why this plane saves money for U.S. taxpayers. That machining makes the plane compelling in ways that have led other countries to take up some of the cost. Here is a look at a high-value, highly engineered machining process for the Joint Strike Fighter aircraft.

-

Milling Toolholder for Heavy-Duty Cutting

Schunk says its Sino-R toolholder is maintenance-free and well-suited for rough milling applications.

-

Flexible, Shrink-Fit Tooling

Shunk’s Celsio shrink-fit toolholders offer the flexibility to combine various shrinking chucks and extensions. This minimizes the number of chuck bodies required to provide a range of diameters.

-

Getting Concept To Car Faster

Joe Gibbs Racing applies a number of workholding techniques to speed the production of racing components its engineering team creates every day.

-

Video: Parts Gripper Allows Machine To Act As Its Own Robot

This footage shows a workpiece gripper that enables a machine to load and unload workpieces on its own.

-

Automation On Demand

A workpiece gripper that installs in a machine tool's spindle enables the machine to serve as its own robot.

-

Hard Milling With Tandem Toolholding

A combination of toolholding choices lets this die shop get the most performance from its small-diameter tools.

-

Toolholder Change Helps HMC Realize Full Machining Potential

An alternate toolholding technology has allowed a shop to achieve much higher spindle speeds on an HMC used to machine short runs of aluminum billet workpieces.

-

Everything Changes

Through a sweeping transition to high speed machining, a Maryland contract shop realizes its goal of same-day, "in by 9, out by 5" turnaround.

-

A New Twist On A Toolholding Technology

This toolholder employs expansion technology similar to that used by high-end hydraulic toolholders at a cost comparable to collet-style toolholders.

-

On The Way To Wireless DNC

Any shop with CNC machine tools has probably wondered how a DNC system could be configured to operate with wireless network connections. Wireless systems are being installed in offices, and even in homes, so that laptops, desktop PCs, and handheld devices can communicate via e-mail, share access to the Web, and exchange data.

-

Why Use Hydraulic Toolholders

The book on hydraulic toolholders is that they are fussy to set, fragile to operate and expensive to buy. So why do many shops choose them over other holders that seem less demanding? This Chicago mold builder has good reasons for its choice.