Sodick, Inc.

601 Commerce Drive

Schaumburg, IL 60173 US

888-639-2325 | 847-310-9000

info@sodick.com

CONNECT

IS THIS YOUR COMPANY?

As Seen On 91ÊÓƵÍøÕ¾ÎÛ

Sodick, Inc. Supplies the Following Products

- EDM Filtration Equipment & Supplies

- EDM Tooling

- Electrode Materials, EDM Wire & Supplies

- Encoders/Resolvers

- for Metal Parts

- Graphite Milling

- Hybrid AM Machines

- Machining Flex Lines

- Nano & Micro Machining

- Powder Bed Fusion

- Ram Type (Die-Sinking) CNC EDM

- Small Hole EDM

- Vertical, Five-Axis

- Vertical, Up to Four-Axis

- Wire Type EDM

Editorial, News, and Products

-

Marathon Precision’s Engineering Playground: One Shop’s Secret to Sustaining High Tech, Low-Volume and High Morale

Half an airplane on the wall, a ten-foot metal dragon, and a full-blown recording studio might not scream “manufacturing efficiency,” yet Marathon Precision proves otherwise. Here’s how forging, complex CNC operations and staff-driven creative projects combine to fuel the shop’s productivity and profitability.

-

JIMTOF 2024 Report: EVs, AI and Autonomous Robots Abound

The 2024 Japan International Machine Tool Fair (JIMTOF) showed how the manufacturing industry is adapting to the needs of electric vehicle manufacturing and adopting new technology including AI and autonomous robots.

-

Trends Shaping the Future of Moldmaking

The demand for high-precision molds produced with greater efficiency continues to fuel innovation in this critical manufacturing niche. Several industry trends and technological developments are driving advancement in mold manufacturing, which are being showcased at IMTS.

-

Sodick Die-Sinker EDM Fits Range of Automation Needs

The Sodick ALG EDM series doubles motor response speed for the development of accurate, high-quality molds, and is equipped with automated features for continuous operations.

-

Sodick Open House Event Will Showcase Machining Portfolio

The company’s Advanced Technology Show takes place on June 6 and 7, 2023, at the company’s headquarters in Schaumburg, Illinois.

-

Wall Colmonoy Acquires New Wire EDM From Sodick

The company will use the new wire EDM machine to increase capacity, improve cycle times, achieve tighter tolerances and improve surface finishes.

-

Sodick Adds Functions to Cut EDM Wire Consumption

Sodick puts a new spin on its ALN, ALP, ALC wire EDM line with new functions that reduce wire consumption by 25%.

-

Stars Slowly Align for Small Shop Merger

RPM Tool’s seemingly overnight expansion from a five-person machine shop to an almost 30-employee production business involved over a year and a half of planning.

-

Sodick Proprietary Linear Drives Maximize Machine Accuracy

Sodick’s K4HL CNC small hole drilling machine and AL G series die-sinker EDMs feature the company’s proprietary rigid linear motor drives for increased accuracy.

-

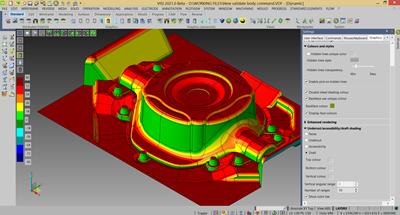

Hexagon VISI 2021 Improves CAD Analysis

Hexagon's VISI 2021 includes new analysis-shading modes to improve CAD analysis.

-

When a Swiss-Type Is a Lathe and a Five-Axis Mill

Swiss-type lathes with a swiveling B axis enable this shop to machine parts complete and unattended that it otherwise couldn’t using its five-axis machining centers. Here is some of what it learned adopting this new technology.

-

Sodick Ushers in an Era of Change Across EDM, Milling and Additive

At IMTS 2018, Sodick is showcasing an era of change with new offerings in its EDM, milling and additive technologies.

-

At a Grand Opening, Sodick Reveals More Than New Machines

Along with launching a new line of hybrid machines, the EDM manufacturer is tailoring one of its EDM models specifically for post processing additive parts.

-

3D Printer Can Run For a Week Hands-Free

IMTS 2018: Sodick’s large-capacity OPM350L metal 3D printer/CNC hybrid expands the usable work area and introduces the Material Recovery System (MRS) unit.

-

June 2018 Product Spotlight: EDM

This month’s Modern Equipment Review Spotlight focuses on electrical discharge machines (EDMs) tailored to a variety of industries.

-

Overcoming the Limits of Hard Milling with EDM

An unusual opportunity led a maker of die-cast dies to reconsider its emphasis on hard milling and take another look at its use of EDM.

-

Wire EDMs Handle Extra-Large Workpieces

Sodick has released two models of wire EDMs, the ALN800G and the ALN800GH.

-

In-Process Correction Technology Added for Hybrid Metal 3D Printer

An In-Process Correction system increases the precision of both additive and subtractive processes inside Sodick’s OPM metal 3D printing hybrid platform.

-

June 2017 Product Spotlight: EDM

This month’s Modern Equipment Review Spotlight focuses on a variety of electrical discharge machining equipment.

-

Hybrid Combines High-Speed Milling with Powder-Bed Additive Mfr.

A new hybrid machining center from Sodick integrates high-speed machining with direct metal laser sintering (DMLS).

-

Sodick Begins Construction of New U.S. Headquarters

The larger facility will be located in Schaumburg, Illinois.

-

Hybrid Machine Enables Milling between Additive Passes

Sodick’s OPM250L combines additive metal manufacturing and high-speed milling into the same workspace, enabling single-process production of finished components.

-

EDM Cell Cuts Lead Time in Half, Improves Quality

Sodick's AG60L sinker EDM and an Erowa Robot Compact helped Ford Tool and Machining LLC cut lead time in half when it needed to reduce downtime and increase repeatability.

-

EDM Features Longer Travels, Improved Wire Threading

Sodick's latest wire EDM, showcased at a recent open house event, also features linear motors, custom base ceramics and other features common to the company's entire line.

-

Wire EDMs Equipped with Pulse Control

Sodick says that its SLN-G series of wire EDMs is designed with the operator in mind with a user-friendly control.

-

Houstex 2015 Preview Slideshow

Click through the slideshow to see a selection of technologies to be displayed at Houstex in advance of the February 24-26 trade show.

-

Sinker EDMs Enable Zero-Electrode Wear

Sodick’s AD series of sinker EDMs includes the AD35L and the AD55L high-performance models.

-

EDM Stabilizes Wire Tension

Sodick's SL400G rigid, linear-motor-driven wire EDM incorporates a Fixed Jet (FJ) automatic wire threader, said to offer accurate and reliable threading rate for both submerged and non-submerged threading.

-

Wire EDMs Reduce Number of Cuts

Sodick offers two models of its SL-G wire EDMs, the SL400G and the SL600G, both driven by linear motors.

-

Attracting the Next Generation while Satisfying the Current One

Sodick’s recent Smart Technology event showcased new machines as well as screen options designed to attract the next generation.

-

High Speed Machining Center Mills Graphite, Copper Electrodes

Sodick’s TT1-400A high speed machining center is designed for precise milling of graphite and copper electrodes.

-

Electrode Machining Center Mills Graphite, Copper Electrodes

Sodick’s high speed TT1-400A electrode machining center is designed for high-precision milling of graphite and copper electrodes.

-

Wire EDM Offers Additional Height

Sodick’s high-precision AG600LH wire EDM incorporates an additional Z height.

-

Wire EDMs Offer Expanded Z Height

Sodick’s AQ750LH and AQ1200LH model AQ series wire EDM machines feature an expanded Z height and linear motor drive technology.

-

EDMs Increase Machining Stability, Accuracy

Sodick offers the AD30L sinker EDM and the AQ400L wire EDM.

-

EDM Brings Capacity, Capability to New Heights

A wire EDM’s increased Z-axis capacity enabled this shop to take on larger parts.

-

Sinker EDM Features Simplified Control Mechanism

Sodick’s eco-friendly AG100L sinker EDM features a simplified control mechanism that provides a direct link between the drive and the control.

-

High Speed Wire and Sinker EDM

The AG40L sinker EDM with linear motor drives offers high speed and high acceleration, which is said to enable an even and natural flushing condition for high part accuracy.

-

Video: Linear Motor Micromachining Center

Video shows the smooth, quiet, rapid motion characteristic of effective micromilling.

-

CAD Input For EDM

This software runs on the wire and ram (die sinking) versions of the company's "LQ" Windows XP-based control unit. The software provides a special interface that allows the user to input 3D solid model geometry directly from the CAD system to use as input to the EDM control unit. Using CAD data as direct machine tool input has long been a dream that developers of other types of machine tools are now closing in on.

-

Reaching New Depths And Greater Accuracy

Just when you thought high speed machining or hard milling would steal the best applications from ram-type electrical discharge machines, linear motor technology is taking "sinker EDM" to levels unattainable with any other metal removal process.