Automation

MAG Expands VMC Production

In response to changes in the global economic environment, Erlanger, Kentucky-based MAG Industrial Automation Systems is adjusting its product portfolio, production sites, sales and technical support network to improve its position in the VMC segment. The company says it will develop larger 2- and 3-meter models of recently introduced VMC product lines, which will be introduced in October 2009 at the upcoming EMO show in Milan, Italy. In the first quarter of 2009, the company’s Chatsworth, California facility will increase VMC production to shorten delivery times, says Mark Logan, vice president of business development and marketing for MAG Americas.

Read MoreAutomated Turning For Small And Large Batches

The VL-Y from Emag is fully equipped with a Y axis (50-mm travel); a chip conveyor; a machining area extraction unit; a fluid-cooling system for spindle motor and turret; and automation equipment for loading and unloading workpieces. The machine features a recirculating workpiece storage conveyor on which “carrier prisms” deliver raw parts and collect the finish-machined components from the pick-up spindle. The pick-up station is located behind the machining area, so the operator can continue removing finish-machined components and inserting new raw parts into the carrier prisms at the front.

Read MoreRobotic Toolchanger For Heavy Automation

The QC-1210, a robotic toolchanger designed for payloads as heavy as 2,650 lbs (1,200 kg), is available from ATI Industrial Automation. The heavy automation toolchanger features three of the company’s patented Fail-Safe locking mechanisms to ensure high moment capacity and strength. Compatible with existing heavy automation toolchanger utility modules, the modular construction allows integration into applications requiring high power, coolant, servo, DeviceNet, Ethernet and discrete-signal capabilities.

Read MoreRobotic Cell Locks In Time, Cost Savings

Having implemented robotic systems in the sheet metal side of its business, this Nevada-based shop wanted to obtain similar automation systems for its CNC machining operations. The Fanuc JobShop Cell from Methods Machine Tools has reduced both costs and cycle times on one of the shop’s most important jobs.

Read MoreGF AgieCharmilles Offers New OSS Smart Machining Feature

GF AgieCharmilles? OSS (Operator Support System) automatically configures cutting parameters to optimize machine performance based on specific job requirements. Standard on any high-speed or high-performance machining center, OSS provides users with an intuitive interface for entering data that is then used to tailor machining processes. When using OSS, operators are asked to rank the relative priority of a job's accuracy, cutting time and surface quality.

Read MoreOkuma Hosts 2nd Interoperability Symposium

The second annual Organization for Machine Automation and Control (OMAC) integration and interoperability symposium is quickly approaching. The event, hosted by Okuma America Corporation, is scheduled for December 3-4 at the Partners In Thinc facility in Charlotte, North Carolina. The keynote speaker is SAP’s Vivek Bapat, who is also the co-author of “In Pursuit of the Perfect Plant.

Read MoreCNC Training Software Uses Actual NC Programs

Siemens Energy & Automation’s SinuTrain CNC training software is designed to run with Windows XP and is said to be suited for machine tool control-identical simulation training. The software is designed to provide mill and lathe operators with a high degree of practical hands-on experience prior to using the CNCs for the first time, the company says. While using the application, NC programs are developed and simulated using a direct connection to the company’s CAD systems to further speed the program generation protocol.

Read MoreAutomation For Chucked Parts

A free-standing parts loading system allows automated material delivery and parts storage so a chucker can run unattended for long stretches of time.

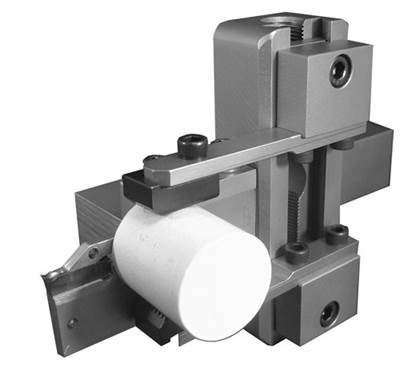

Read MoreOne Tool, Two Turning Functions

A combination bar puller and cutoff tool is an inexpensive way to enable short stretches of unattended turning while saving a turret position.

Read MoreA New Spin On Parts Collection

How do you manage the parts your bar-fed lathe creates overnight? An indexing collection device can serve as an effective means to safely collect precision components.

Read More