Data-Driven Manufacturing

DNC: A Growth Path to Machine Monitoring and Data Collection

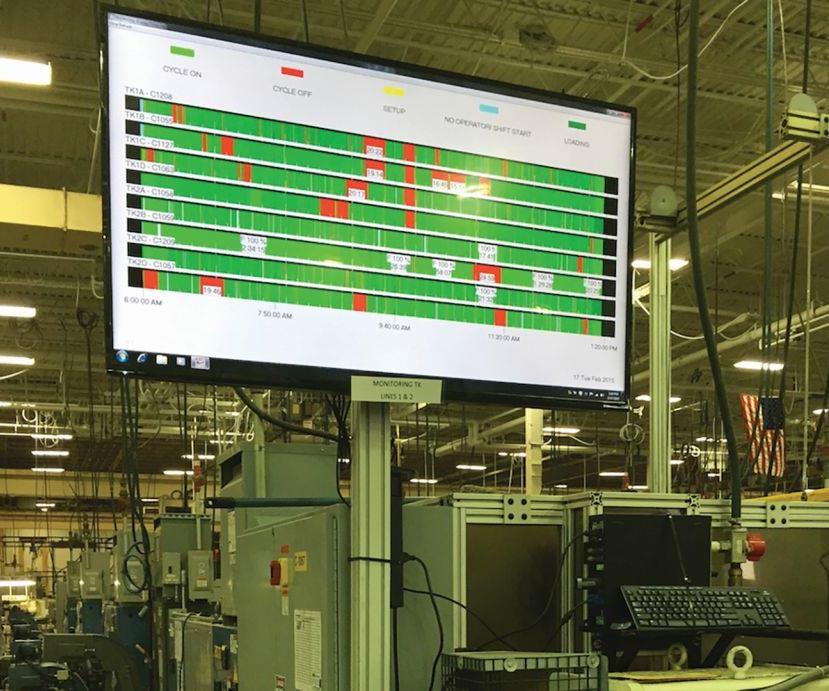

The connections that enable operators to download tool paths and other files can also be used to report machine status automatically as well as streamline manual entries of production results.

Read MoreDelivering Value Is Key

Machine data requires contextual interpretation to give decision makers a full understanding of what actions are best for optimizing shop floor results.

Read MoreMonitoring Spindle Bearing Health

Caron Engineering’s Tool Monitoring Adaptive Control (TMAC) now has the capability of monitoring spindle bearing health.

Read MoreMachine Data Collection Software Eases Analysis

Shop Floor Automations offers version 11.0 of Predator MDC machine monitoring and data collection software.

Read MoreTechSolve Appoints Chief Commercial Officer

Rick Gambaccini will oversee new product development and commercialization.

Read MoreManufacturing News of Note: January 2017

Okuma showcases IIoT-enabled technologies, a large welding machine is getting developed for lightweighting R&D, and other industry news.

Read MoreWalter, Comara Announce Joint Venture

The venture is intended to expand the partners’ smart manufacturing product offerings.

Read MoreWhat It Takes to Connect

Development of the IIoT brings with it new requirements to control, monitor and analyze these massive amounts of data, and convert them into actionable business intelligence in real time.

Read MoreJIMTOF 2016 Report: Exhibitors Show a Strong Embrace of IIoT

The recent Japan International Machine Tool Fair reflects the rapid move toward smart factories in which smart machines are fully networked.

Read More