Data-Driven Manufacturing

Impressions of IMTS 2016

Things changed this year. New technologies and a new generation were prominent, and together they are helping to take this show into its next era.

Read MoreMaking Connections

The networks of connected shopfloor devices that underlie implementations of data-driven manufacturing come together on many levels. All are worth noting.

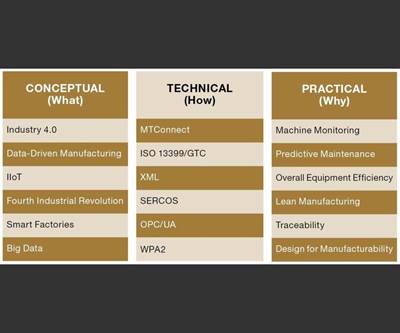

Read MoreData-Driven Manufacturing Deconstructed

"Data-Driven Manufacturing" can be broken into three areas for better understanding: the conceptual, the technical and the practical.

Read MoreItalian IIOT: Cautious but Confident

Although The Industrial Internet of Things (IIOT) was a popular topic at Bi-Mu, the biennial machining and manufacturing exhibition in Milan, Italy, technology suppliers seem to have adopted a cautious outlook.

Read MoreFive Tips for Effective Machine Monitoring

A machine shop’s successful entry into machine monitoring reveals important points about what to do and what to expect.

Read MoreLarge, Made to Order and Ready to Connect

The 30th edition of the Bi-Mu trade show in Milan, Italy, highlighted not only modular machine tools for work like machining aerospace structures, but also technology related to the Industrial Internet of Things (IIoT) and more.

Read MoreRotational Sensors Achieve Stable Signals Even at Low Rotation Speeds

Rheintacho’s rotational speed sensor, the Rheintacho FE, includes one-channel, two-channel and PWM-signal output sensors installation-compatible with highly compact housings.

Read MoreConnectivity Board Connects Legacy Machine Tools

Memex introduces the MTC-One, an MTConnect connectivity board for legacy machine tools and Industrial Internet of Things (IIoT) devices.

Read MoreRemote Monitoring System Installs in Less than 20 Minutes

Smart Attend is an all-in-one solution to complete manufacturing facility communication, capable of collecting and organizing data for Pareto analysis and providing individual manufacturing goal parameters.

Read MoreStreamlining the Data Network Inside a Machine

As machine tools become more capable of generating data about events and changes that occur within the machine’s internal control system, and the “smart” sensing or measuring devices connected to it, managing this inner network becomes a challenge.

Read More