Holemaking

What Don’t you Like About that Canned Cycle?

Almost all CNC users take advantage of control-based canned cycles. Even CAM systems commonly output G-code programs that contain canned cycle commands. This includes hole machining canned cycles, such as drilling, tapping, boring and more, and whatever milling cycles the machine may have. For turning centers, it includes roughing and finishing multiple repetitive cycles.

Read MoreBenchmark Your Machining Knowledge

Ryan Pohl, president of Expert Technical Training, says his company gives a 20-question, multiple-choice test to shops to evaluate their need for his firm’s “Advanced CNC Milling and Drilling” course. The questions cover important points—though not necessarily basic points—related to tools, toolholders, machine design and cutting parameters. Here is a link to the questions.

Read MoreJust don’t Call it Vibration

The device for rapid peck cycles holds the drill like a toolholder.

Read MoreAdvanced CNC Milling and Drilling Quiz

A provider of machine shop training offers these questions for benchmarking metalworking knowledge.

Read MoreDrilling with Modulation Delivers Pecks for Free

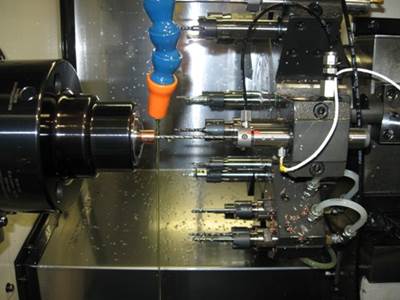

A system for center drilling on Swiss-types and other small lathes oscillates the drill up to 1,000 times per second. Cycle time, part quality and predictability all improve.

WatchVideo: Modulation Assisted Machining

This footage shows the effect of a techology that speeds and simplifies center drilling by oscillating the drill through many pecks per second.

WatchProgrammable Five-Axis Spindle Head Attachment

Tri-Tech Precision Products’ model 5414-R3 programmable spindle head attachment can provide virtually any three-axis CNC milling center with true simultaneous five-axis milling, grinding and drilling capability.

Read MoreDrill and Tap Machine Features Milling Capability

Haas Automation’s DT-1 is a high speed drill and tap machine is also capable of milling operations.

Read MoreThe Importance of Float During Micro Reaming

Micro reamers require a floating holder to compensate for any machine positioning inaccuracies.

Read More