Holemaking

Drilling Solutions Improve Tool Life, Cut Cycle Times

Interruptions due to worn or failed tools can be especially detrimental to productivity, especially on parts with lengthy cycle times. At a manufacturer of large commercial heat exchangers, many of which require drilling of hundreds of holes, the improved tool life of Precision Dormer’s Hydra and CDX-Inox drills led to significant cost and cycle time savings.

Read MoreA Deeply Holistic Approach

In its effort to streamline every step of the mold building process, this company has upgraded its deep-hole drilling capability with a new six-axis machine. A rotary table with magnetic workholding enhances this machine’s flexibility.

Read MoreUniversal Milling Machine For Complex Applications

Suited for vertical milling, drilling and tapping, Knuth Machine Tools USA’s VHF 3 universal milling machine also includes a horizontal arbor for horizontal milling, slotting and keyway cutting. The machine is useful for mechanic workshops, production, training, single-part manufacturing and prototyping.

Read MoreModular Drill Diameter Range Expands

The Ken TIP modular drill system from Kennametal features various solid-steel bodies (3 × D, 5 × D and 8 × D, among others) and replaceable drill points for precision hole-making in steel. The modular design allows users to keep the drill bodies in a machine or holder and replace drill points as needed. Running at speeds comparable to those of solid carbide drills, the system offers high metal removal rates compared to common modular drills and reduces setup times, the company says.

Read MoreModular Drills Combine Benefits Of Indexable Tools

Kennametal says its KSEM Plus modular drills combine the high feed rates and length/diameter capabilities of modular drills with the high speed and low consumable costs of indexable drills. The drills offer increased metal removal rates and productivity in various applications, including the energy market. The drill bodies accept a range of head diameters, and inserts or heads can be replaced without removing the body from the spindle.

Read MoreHole-Finishing Tools Designed For Fine Surface Finishes

The company’s line of hole-finishing tools includes Burraway and Burr-Off mechanical deburring tools for controlled edge break or burr removal on both sides of holes in one pass. Shefcut precision reaming and boring tools which are designed for accurate size, fine finish and superior hole geometry are also available. Tools for burnishing include multi-roll, single-roll, and diamond burnishing tools, which are said to provide for accurate sizing, fine finishing, and work-hardening of bores and shafts in seconds.

Read MoreCobalt HSS Drill For Deep-Hole Drilling

For deep-hole drilling, the company offers the Helios 15D and 20D cobalt HSS drills. The drills can process deep holes without the use of an internal coolant supply and without pecking. The flute design improves chip evacuation, making it feasible to drill as much as 20 × D without pecking.

Read MoreTapping Holder Improves Thread Quality And Tap Life

The Mega Synchro tapping holder compensates for synchronization error during rigid tapping by reducing the thrust load to both the tap and workpiece, improving thread quality and tap life. This is facilitated through a mechanism that absorbs the pitch difference between the tap and synchronous spindle. Capable of supplying coolant through slits to the tap periphery, the holder is available in various lengths and spindle interfaces to suit any company’s needs.

Read MoreMicromachining: Drilling Is Doable

This shop drills 0.020-inch holes as part of a machining cycle that also includes full-size tools cutting full-size features.

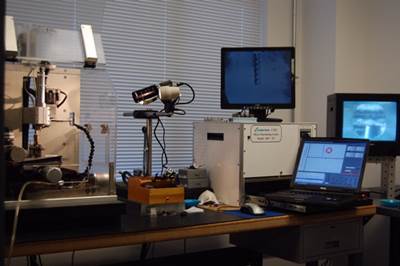

Read MoreVideo: Drilling 0.020-Inch Holes In Stainless Steel Aerospace Part

This footage on a small drilling machining also includes machining with full-size tools in the same cycle.

Watch