Milling Tools

Milling Cutter for Roughing, Finishing Cast Iron

Sumitomo Electric Carbide says its SumiMill Goalmill milling cutter accurately finishes cast iron.

Read MoreTool Line Complements Titanium, Stainless Techniques

A notable trend over the past five years or so has been the evolution of techniques for machining hard, difficult-to-cut materials, particularly titanium and stainless steel.

Read MoreVariable Geometry End Mill

OSG Tap & Die’s HY-PRO CARB VGx variable geometry end mill is designed for chatter-free, high-performance machining of a range of materials.

Read MoreHigh-Performance Thread Mills

Niagara Cutter’s line of high-performance carbide thread mills is designed for productive, consistent machining of high-quality threads.

Read MoreThe Many Ways Ford Benefits from MQL

Clean machining using minimum quantity lubrication has allowed Ford’s Van Dyke transmission plant to become fundamentally more efficient and effective at manufacturing six-speed automatic transmissions.

Read MoreIndustry’s First General Purpose, High Performance Tap

(Sponsored Content) MultiTAP from Emuge is the industry’s first high performance tap designed to cut a wide range of materials including carbon steel, steel alloys, stainless steel, aluminum, cast iron, copper, brass, and bronze. MultiTAP is also uniquely designed to produce threads within both 2B and 3B classes of fit, eliminating the guesswork of calculating H-limits.

Read MoreCarbide Milling Cutters for High-Productivity Metal Removal

Seco’s Jabro-Solid2 (solid square) carbide milling cutter is available in sizes ranging from 1/8" to 1". The versatile, square-shoulder mill is designed for both wet and dry general-machining applications in a variety of materials, including carbon steels, gray cast iron, stainless and super alloys.

Read MoreMills for Higher Removal Rates at Moderate Feeds

Iscar says its new milling cutters increase productivity in heavy roughing applications on limited-feed machines.

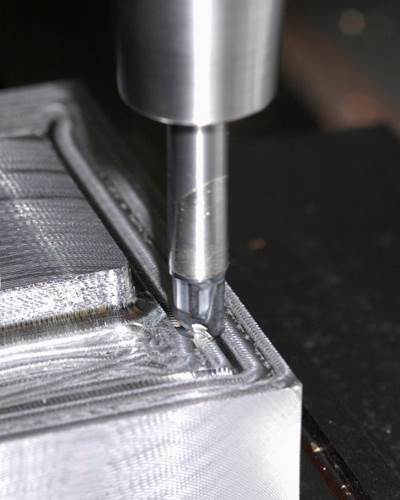

Read MoreIndexable Mills Speed Cavity Cutting

Ballnose mills are a common choice for hogging out cavities on molds and form dies. However, these three shops have realized significantly faster cavity milling by switching to Ingersoll’s Chip Surfer modular tooling system, which features a cylindrical shape that keeps more of the tool engaged in the cut.

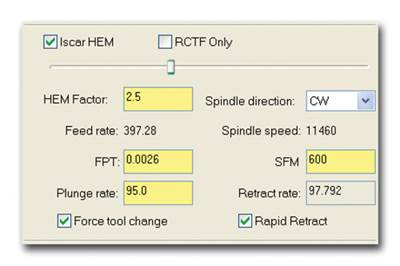

Read MoreSoftware/Tooling Partnership Promises Easier HSM

High-efficiency parameters are calculated automatically—partly using a slider that lets the programmer set the level of aggressiveness.

Read More